Company News

Chaeng GRM vertical mill upper shell detailed

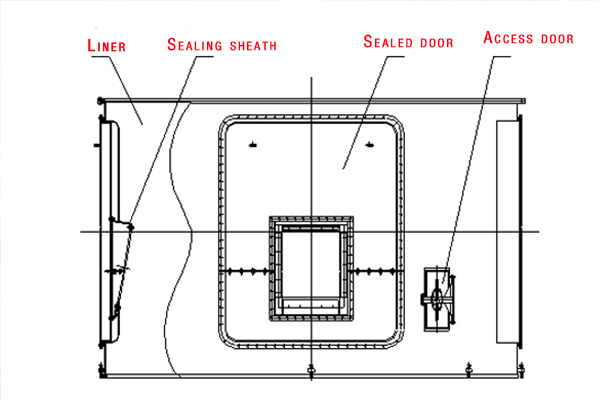

The upper shell of chaeng GRM vertical mill is welded structural parts. The cylindrical housing is welded to the holder of the vertical mill. On the housing, a sealing door is opened so that the rocker arm and the grinding roller can be freely turned in and out. Each access door is provided with a sealed door, a sealing sheath is arranged on the sealing door, and a rubber sealing plate is used between the rocker arm and the sealing sheath to seal. A liner is placed inside the housing and can be replaced after wear. In order to conveniently check the inside of the vertical roller mill, there are two access doors on the housing.

1.Features

The upper housing forms a closed grinding chamber, and secondly a space is formed for the gas dust to rise from the grinding disc to the separator. The middle casing carries the weight of the separator.

2.Maintenance

Check the wear of the liner.

The seal cover should be inspected periodically to see if it is broken. If necessary, it should be replaced in time.

The "0" position of the grinding roller can be verified by means of a scale mounted on the grinding roller and a pointer mounted on the housing. To achieve this, the grinding roller must be lowered until it comes into contact with the disc liner. In this position, the pointer can be adjusted to the "0" position on the scale. When the mill is running, the scale is moved to a fixed scale position, so that the average thickness of the bed and the variation in thickness can be read.