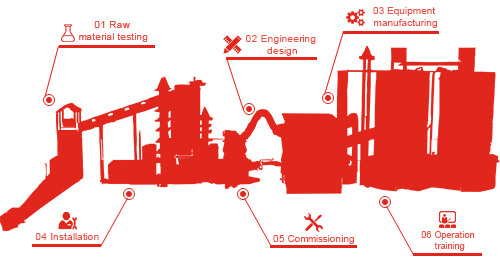

Chaeng delivers reliable cement project execution for cement plants using advance cement machineries With the manufacturing of individual components of cement plants and with fabrication, installation & commissioning of entire cement plant, Chaeng has supplied & commissioned more than 150 Cement Plants We execute turnkey cement projects for Cement Plants, Rotary Kiln Cement Plants, Vertical Shaft Cement Plants, Clinker Grinding Units, Slag Cement Grinding Units and Slag Grinding Project For successful implementation of our turnkey cement projects, we conduct various types of project development studies, feasibility studies etc These are followed by engineering, procurement & construction management (EPCM) services We supervise the construction, commissioning along with offering start-up and post start-up services

The new dry process cement production line with capacity of 1500 t/d, build by our company, is rationally equipped with advanced equipment for grinding the majority of raw materials. The limestone crushing uses TKPC16.18 single-section hammer crusher, whose feeding size is 800 mm, production capacity is 250 t/h, and annual utilization rate is 25.51%.

This production line design adopts scientific material piling and taking technology, to achieve the initial raw material homogenization. Thus the stock ground has the function of both storage and homogenization.

The energy consumption in cement grinding process accounts for more than 60% of the whole production line, therefore, it has great significance in ensuring product quality and reducing energy consumption by using high efficiency and energy saving GRM series vertical roller mill to deal with all kinds of material.

The line is equipped with φ15×50mMF homogenization silo which integrates raw meal storage and homogenization. The raw material reserve is 6500 t, with 2.86 d storage life.

Raw materials are sent into φ3.5×54m rotary kiln to be calcined after preheating and precalcining in the cyclone preheater. That is conducive to improve the production efficiency of kiln system, shorten rotary kiln length, and reduce the heat consumption of clinker calcining.

Clinker grinding equipment uses GRMK40.41 (2 + 2) cement vertical mill developed by our company. It makes use of exhaust stem from preheater outlet (300-330) as the drying heat source. Cement vertical roller mill has the characteristics of simple technological process, safe and reliable operation, high grinding efficiency, low power consumption, less maintenance, and short debugging cycle, etc.