Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials

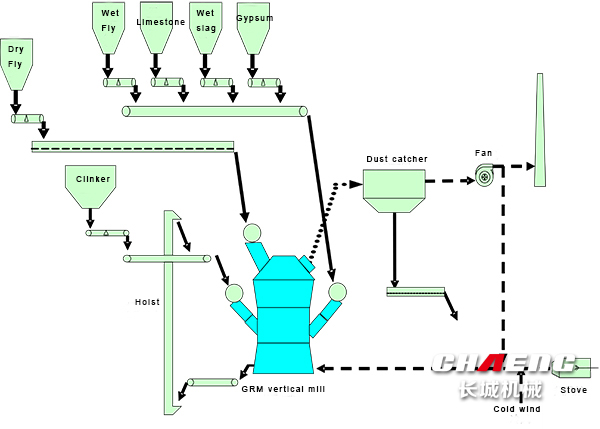

This vertical cement mill is widely used in the grinding of cement raw meal, slag(GGBS), cement clinker, raw coal and other raw materials. It gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% ). The vertical roller mill adopts dynamic powder selecting device, which comes with high powder-selecting efficiency and convenient adjustment of fineness.After crushed by crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.The grinding disc is driving by motor through reducer.

The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers. Then, the hot air from the nozzle take the fine powder to high effiency classsifer.

The qualified powder are taken by the air to the powder collector to be collected, while the unqualified powder are sent back for regrinding.

1. Technique and technology is mature and stable

GRMK series Vertical cement mill have the ability completely to replace tube mill in the production of cement, for the reason, the cement specific surface area can be up to 3800 cm²/ g with stable and reliable quality.

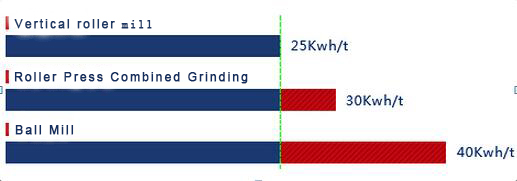

2. Reducing the power consumption of cement clinker preparation effectively

According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and the power saving effect is very remarkable.

3. Stable, high-efficiency and environmental protection

The vibration noise in overall system is low and equipment with whole sealing system working under negative pressure with no dust overflow. Therefore, cement vertical roller mill meets the national environmental protection requirements. With working mechanism changing, cement vertical roller mill can be reduced friction and improved service life.

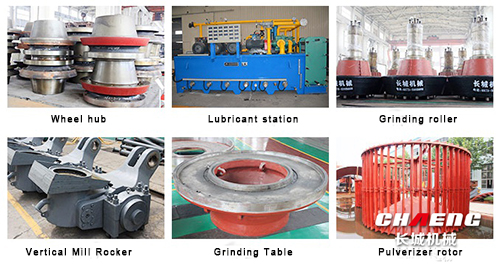

4. With a strong casting capability and short delivery period

Great wall is the third enterprise which has a large-scale complete set casting company in domestic, and it can meet casting capability of single 120t, meanwhile, it has a large-scale machining workshop, can reduce the delivery period of cement vertical roller mill greatly.