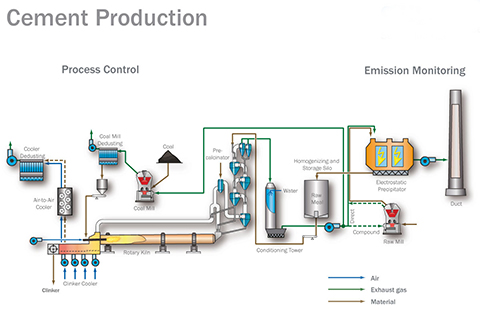

Xinxiang Great Wall Machinery has a history of more than 50 years and has accumulated rich experience in cement machinery At present, we have been able to supply 300-5000 t d cement EP project, providing solutions for the world s growing demand for cement 2500 t d cement production line designed by Chaeng, fully learns from the lessons and experiences of more than 20 years of NSP production line design,and combines with today s international advanced production concept to optimize design It’s composed of raw materials preparation, raw meal grinding, raw meal homogenization, clinker burning, cement mill grinding, packaging, delivery and so on The cement equipment in the production line include: raw materials vertical roller mill, vertical coal mill, cement rotary kiln, cement ball mill, cyclone preheater and grate cooler, etc

Compared with traditional cement production line, the 2500 t/d cement plant designed by Chaeng uses lower energy consumption equipment in the main part of energy consumption, such as vertical raw mill, vertical coal mill, vertical cement mill, etc., and the energy saving effect is very significant, which can reduce energy consumption with an average of 15-20 kWh/t.

Cement production has always been one of the leading causes of environmental pollution, thus more and more cement plant is looking for a solution to reduce noise and dust pollution. Chaeng fully considers the sustainable development in the design, reducing dust through campus greening, filter, etc. Since the introduction of noise control programs in key areas, the factory noise is lower than the national standard.

With large supporting cast steel companies and large machining workshop, Chaeng has 120 t casting ability, can supply complete spare parts. Furthermore, with a variety of long-term cooperation and first-class equipment suppliers, it greatly shortens delivery cycle, and makes your profit in the shortest possible time.