The rod mill is loaded with the grinding media of steel bars It consists of five parts including cylinder shell, feeding system, discharge system, main bearing and transmission system

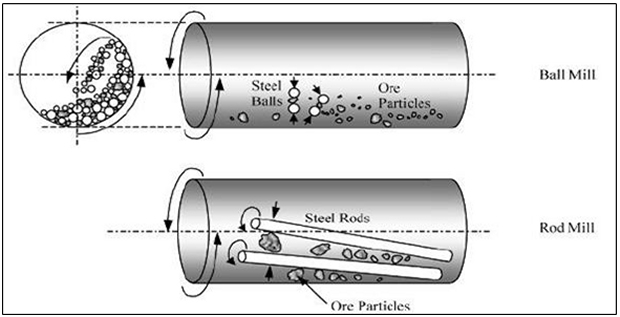

The rod mill is loaded with the grinding media of steel bars. It consists of five parts including cylinder shell, feeding system, discharge system, main bearing and transmission system.

It is available for both of the dry grinding and wet grinding fashion as the customer’s needs.

By using a new advanced technology of inlet and outlet control, we can match the befitting grinding media according to your material property, which will make the discharge size well distributed.

Compared with the sliding bearing of the old rod mill, our new equipment can save you 10-20% energy in total. The production is improved more than 10% than usual.

The experienced technology design on the specification can promise you a well running situation with less over crushing problem.

We have supplied numberless of wet grinding rod mills for customer in coal chemical industry, to deal with the coal and petroleum coke material and prepare for the coal water slurry making.

The mill can design as the first level open circuit grinding equipment, which can be widely used in the department of manual stone sand, ore treatment plant and chemical plant, etc.