Company News

Industrial slag grinding equipment-Vertical mill—Great Wall machinery

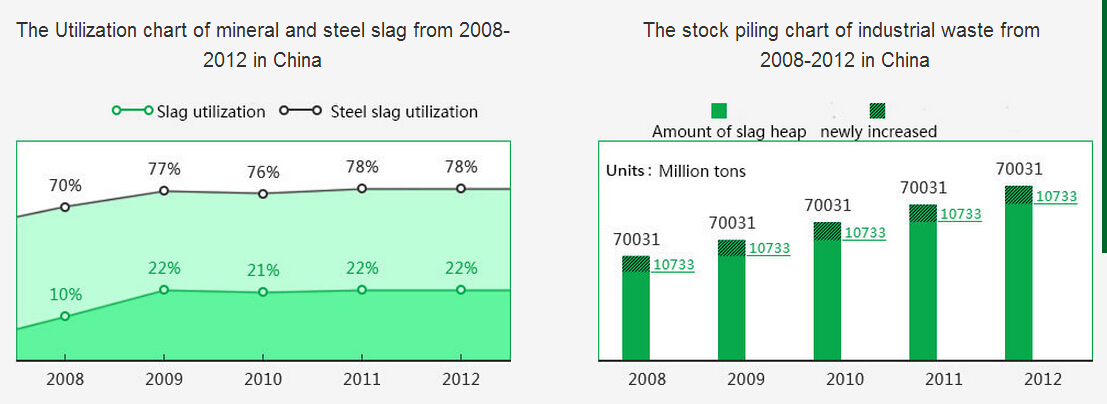

01 The process of industrial waste treatment is imperative

Recently China gives regulations and fine standards about industrial waste resource: 25RMB per ton for Smelting slag, 30RMB per ton for fly ash, 25RMB per ton for general slag, 5RMB per ton for Gangue waste (and so on) is one-off levied as waste discharging fee by state department, from 1st July. 2013. Therefore, the process of waste treatment, no matter steel slag, mineral slag, nickel slag, manganese slag or others, is gradually valued by more and more companies in this field.

The integrated vertical grinding system, pioneered by Great Wall Machinery, can deal with all the slag mentioned above. It has been tested and verified by more than 60 companies in China, and also benefits millions of money for them.

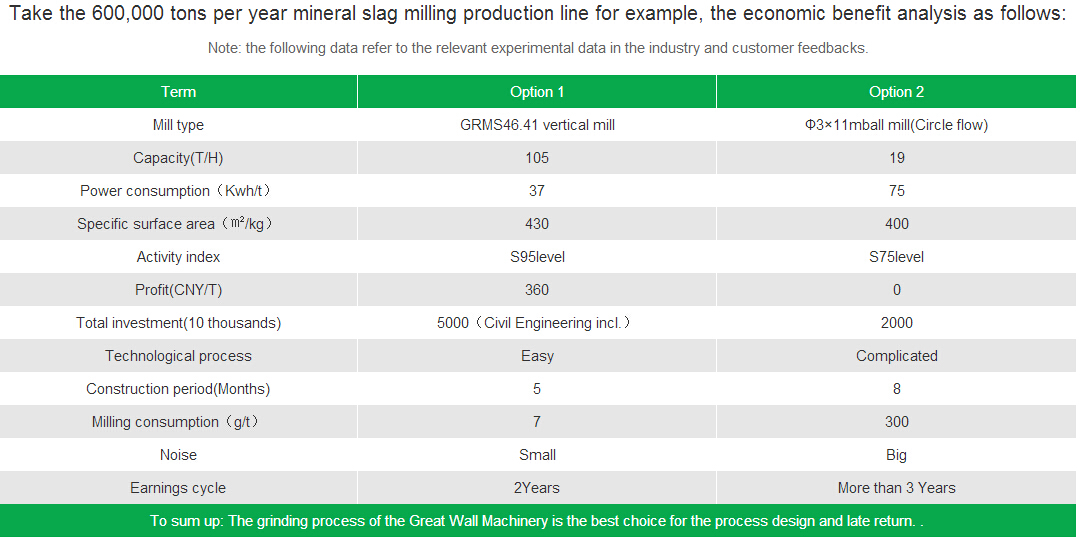

02 Better ROI(return on investment) rate:Recover costs in 1-2 years

03 Mature clients’design:6 services in one vertical mill

04 The advantages of Great wall Machinery

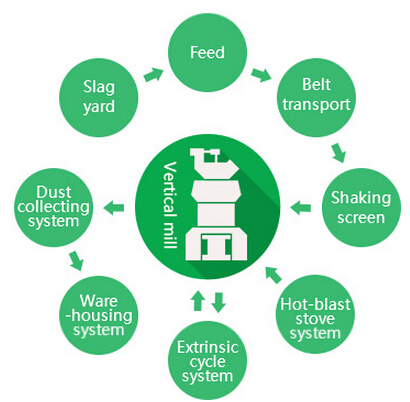

Mineral slag processing

1.The slag by the car into the factory, the unloading hopper, the belt conveyor into the slag heap storage

2.The final slag fetched by the car into the unloading hopper, the belt conveyor into the slag heap storage after feeding calculation.

3.After drying and grinding process, the slag powder collected by long bag pulse. Then, they will be transferred to stock through air slide and hoist.

4.The split slag is fed to magnetic separator through belts, hoist.

5.The heat resource, during on milling and drying process, is provided by hot blast stove in front of the mill.

Advanced grinding system

Lower investment costs, Intelligent control

Gathering crushing, drying, grinding, selecting, transporting processes as one machine, the grinding system only takes 50% covered area compared with ball mill system. It is compacted layout and also can be installed out-doors. There is PLC/DCS intelligent control system on the mill, and can be easily remote control.

The degree of fineness can be adjusted

The advanced, high efficient and cage-style rotor separator ensures the specific-surface-area adjusting range between 400-550 ㎡/kg, and satisfy the fineness requirement from clients.

Less than 40KWH electrical consumption.

The level milling plate and conical rollers guarantee the material cushion stable enough, which means lower electrical consumption. 30-40% power is saved comparing with ball mill system.

Environmentally friendly and easy maintenance.

There is no dust-leaking because of negative pressure state, which leads the clean working environment and meet national environmental protection requirements. Changing grinding plates and rollers only needs spinning rocker and cylinder, which reduced the shut-down time.

Original accessories

All the roller, grinding plates, rockers and other spare parts are originally manufactured by Great Wall Machinery, which means the quality and timeliness is guaranteed.

360RMB per tone in mineral/metal recycling process.

The rate of pig iron recovery could be as high as 0.2-0.3% by specially designed iron separator. It can produce 360 RMB per tone income when dealing with mineral or nickel slag. Recycling the iron also can reduce the consumption of spare parts on the mill, and as a precaution of metal concentrate, which is harm for the milling system.

05 Great Wall strength

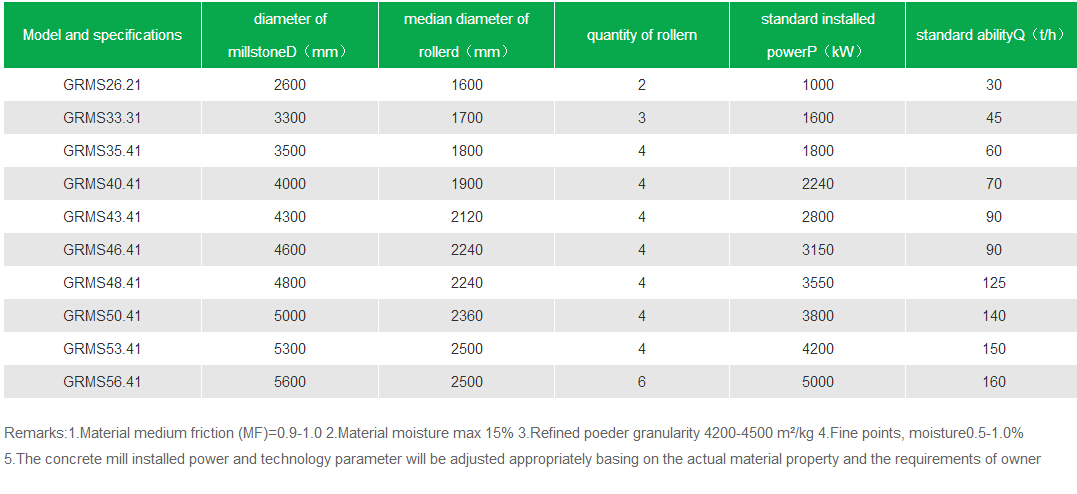

06 Technical Data