Industry Knowledge

casting steel slag pot

Industrial cast steel slag pot is widely used in metallurgy and casting industry. It is a kind of container that takes up steel slag.

Slag pot can be divided into three parts slag body, trunnion and turning mechanism.

Generally speaking slag body is made from casted steel, trunnion and turning mechanism are which made from forged steel. We could also produce slag pots by whole casting according to customer request.

After our engineer team and production people’s long-time effects,our quality is stable & excellent and has win good reputations in China and overseas market like Japan,Russian,the USA,Mexico,etc…

Product Details for industrial cast steel slag pot

Volumn: 3~45 cubic meter

Net Weight: 10~85 ton

Application: steel plant, foundry plant

Material:carbon steel & low alloy steel

Inspection: MT for trunnion area and UT for whole part.

Cooperate with big steel group like SMS, POSCO, JFE, etc…

Material

Cast Steels with differing chemical compositions but defined mechanical properties play a dominant role in the manufacture of slag pots. Standard specifications of Cast Steel for slag pots may be found here:

Country | Specification | Grade |

United Kingdom | BS 3100:1991 | 425-A2 |

USA | ASTM A27 | 60-30 |

Germany | DIN 17182 | GS16Mn5 |

Japan | JIS G7821:2000 | SC42 |

International | ISO 3755:1991 |

Mechanical properties for industrial cast steel slag pot are given below:

USA(MPA) | Europe (MPA) | |

Tensile strength | >414 | >448 |

Yield strength | >207 | >241 |

Elongation | >24 | >35 |

Reduction of area | >35 | >40 |

type

Name | Dimension | Weight | Filled volume |

Round Slagpot | 4.440 x 3.700 x 3.050 | 26Ton | 17CBM |

Round Slagpot | 5.100 x 3.260 x 3.500 | 33Ton | 16CBM |

Round Slagpot | 5.350 x 4.150 x 3.250 | 34.3Ton | 23CBM |

Round Slagpot | 5.200 x 4.040 x 3.050 | 32Ton | 20CBM |

Round Slagpot | 4.660 x 3.600 x 3.200 | 26Ton | 16.4CBM |

Oval Slagpot | 4.700 x 3.890/5.180 x 3.120 | 40Ton | 25.5CBM |

Oval Slagpot | 4.065 x 3.430/4.450 x 3.050 | 30Ton | 19CBM |

Round Slagpot | 5.250 x 4.400 x 3.000 | 34.5Ton | 18CBM |

Oval Slagpot | 3.990x4.075x2.680 | 21.5Ton | 16CBM |

Round Slagpot | 4.825x4.240x3.275 | 38Ton | 23CBM |

Oval Slagpot | 5.840x6.004x3.900 | 60Ton | 45CBM |

Round Slagpot | 5.02x4.58x3.15 | 40Ton | 28CBM |

Oval Slagpot | 4.29x3.61x3.48 | 35Ton | 21.4CBM |

Oval Slagpot | 3.245x3.8x2.85 | 19Ton | 14CBM |

Petals rim Slagpot | 3.4x3x2.374 | 13.5Ton | 6.2CBM |

Oval Slagpot | 2.71x2.3x2.275 | 9Ton | 6CBM |

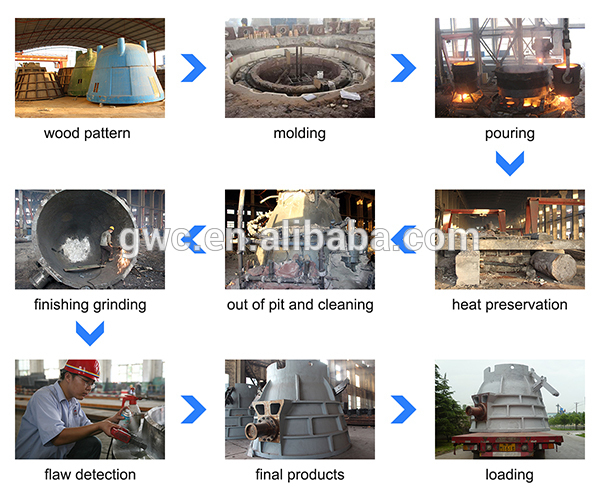

Production Process of industrial cast steel slag pot

Why Choose Us ?

Before production we do strict process analysis and quality valuation with Huazhu brand CAE software.

Use material with good plasticity and high melting point. Add some alloy elements to improve strength and to prevent crack.

Modern technology is available to make pots with “cast in forged trunnions” and also with “interference fit forged trunnions (by cryogenic process)”, to provide the strongest trunnions for a safe operation.

Do 360°nondestructive inspection for inner wall, trunnion and turning mechanism.

Our industrial cast steel slag pot are very smooth inside. No worry to hang slag for use.

Great Wall Steel Casting offers also its expertise on technical advices to customers on the best operational procedures and on the best repair methods to achieve the maximum life of pots.