Industry Knowledge

High safety cement vertical roller mill In China

Introduction of cement vertical roller mill

cement vertical roller mill is one of the most important cement equipment. It is the key grinding machine of materials being crushed. The cement grinding mill plays a vital role in cement production line and cement production process. Cement mill is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and non-ferrous metals beneficiation, ceramics and other production industries. It makes dry or wet grinding for all kinds of ores and other grind-able materials.

Advantage of cement vertical roller mill

1.High-performance separator and optimised airflow ensure high separation efficiency and low pressure loss for energy saving.

2.Unusually large rollers permit coarse feed and ensure a thick grinding bed for maximum uptime.

3.All impact forces and dynamic reactions are small and vertical therefore easy to accommodate – prevents mill stops.

4.Segmented wear parts for table and rollers allow use of the most wear-resistant materials and hardfacing for long life.

5.Reversible roller segments ensure high material utilisation.

6.External circulation limits power consumption of fan.

7.Feed sluice ensures low false air flow and steady feed flow for minimum power consumption and optimum mill production.

8.The raw mill is easily adaptable to high airflow required by especially wet easy to grind materials.

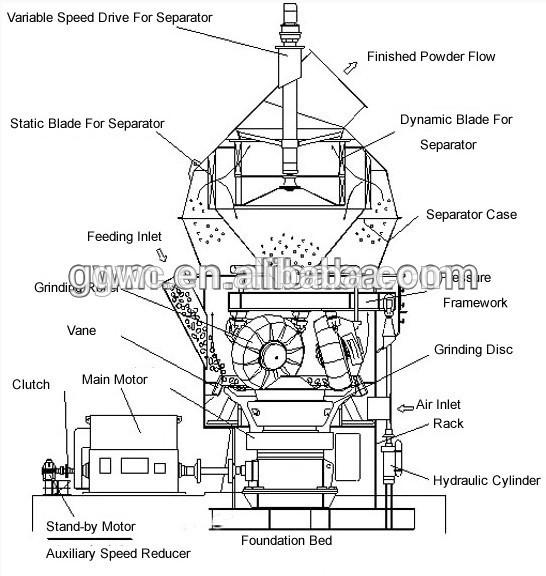

9.Working Principle of cement vertical roller mill

In a vertical roller mill, materials to be ground fall upon the center of a rotating grinding table. Centrifugal force causes the materials to spread out evenly towards the edge of the plate. As particles lying flatly on the plate reach a certain thickness, they are ground or crushed by multiple pairs of rollers.

When the crushed particles fall off the edge of the grinding table, they are met by a strong flow of hot air that has just passed through the nozzle ring at the bottom, which brings them through the center of milling chamber and out the top before entering the separator. During this process, the flying particles absorb enough heat from the hot air, causing the moisture contained in particles to evaporate rapidly.

Once inside the separator, particles finer than the required size pass through the separation device while larger ones fall upon the grinding table once again for further grinding. The desired fully-ground particles enter the finished product warehouse.

Date of cement vertical roller mill

| Model | Grinding Table Diameter (mm) | Roller Diameter (mm) | Roller Number (n) | Motor (kw) | Output (t/h) |

|---|---|---|---|---|---|

| GRMK30.31 | 3,000 | 1,600 | 3 | 1250 | 55~60 |

| GRMK32.31 | 3,200 | 1,700 | 3 | 1600 | 65~80 |

| GRMK35.41 | 3,500 | 1,800 | 4 | 1800 | 85~100 |

| GRMK40.41 | 4,000 | 1,900 | 4 | 2500 | 115~125 |

| GRMK43.41 | 4,300 | 2,120 | 4 | 3000 | 135~145 |

| GRMK46.41 | 4,600 | 2,240 | 4 | 3350 | 150~160 |

| GRMK48.41 | 4,800 | 2,240 | 4 | 3550 | 170~180 |

| GRMK50.41 | 5,000 | 2,360 | 4 | 3900 | 190~200 |

| GRMK53.41 | 5,300 | 2,500 | 4 | 4600 | 210~230 |

| GRMK56.61 | 5,600 | 2,500 | 6 | 5300 | 235~250 |

Note: Mill spectral pattern benchmark

(1)The cement standard: PC42.5 specific surface: 3300~3800cm² /g;

(2)Confirm the compounding ingredient at the time of type selection; choose the lower limit when friction is not well;

(3)Can choose 2 roll mode as per situation of the user.