Industry Reports

What are the core system of the cement production line?

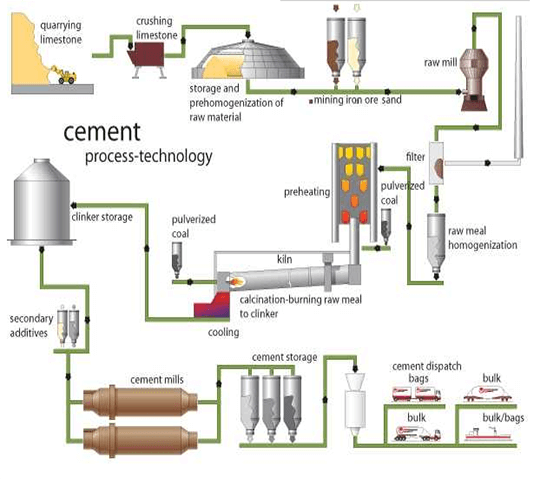

Although the cement production line scale is relatively large, in fact, most of the process is the transport section, the entire cement production line main core section are: cement kiln system, rotary kiln system, cement grinding station, grinding system. These are the core equipment of the entire cement production line, which dominated the entire production process of the production line. Here is the introduction of several major systems:

1, the cement kiln system

Cement kiln is the main unit of cement produced by the firing raw material to clinker of the whole process is the conclusion of the kiln, rotary kiln is the most simple dry kiln. Raw material powder to participate in the kiln, coal with primary air is injected into the kiln and burned in the kiln, the flame temperature here reached 1800-2000 ℃. Raw material in the kiln to kiln continued activity, humidity gradually increased, by drying, dehydration, preheating, differentiation, when the liquid phase rendered about 1300 ° C, below the flame was raised to 1450 ° C to burn mature material, then cooled to 1300 ~ 1100 ℃ kiln falls from single cylinder cooler, cooled to about 100-150 ℃ unloaded onto conveyor transported to the clinker clinker crusher, the crushed warehouse storage.

2, the kiln system

Generally kiln will be installed 3.5% gradient, the number of revolutions per minute is usually less than one revolution, the new dry kiln may be greater than 3 revolutions per minute. Rotary coolers and kiln are substantially the same, not the same cylinder fitted with lifting plate to accelerate the clinker cooler. kiln head hot zone temperature is too high, once the water has cooled, now has been changed to use air cooling.

If the process of cement production technology as a complete system, the final product is cement, clinker are semi-finished products, so the system can be separated from it. the first stage is to collect material to be made of clinker, the second stage is made of cement and clinker shipment delivery. Under normal circumstances, it should be these two phases together, so take up less land, easy handling, with less artificial, to completely centralized control. However, in some special cases separated again more favorable.

4, the grinding system

Ball mill is the first industrial production of cement grinding equipment utilization, and now still dominant, despite its low power, such as the destruction of power by a single particle accounting only 6% to 9%, but the ball mill is simple operation, high reliability, in particular for cement clinker grinding, particle shape and grading of goods suitable cement good performance, the current is also difficult to find able to completely replace the equipment.