Industry Reports

The market position of active lime production line

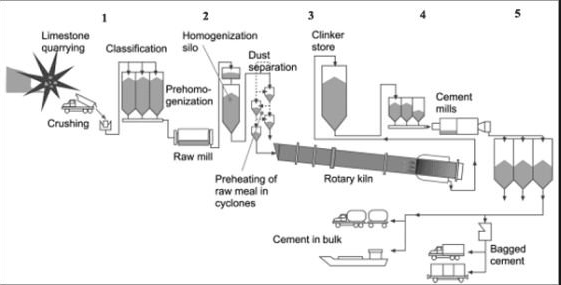

Today, the cement industry development and transformation has become a topic of common concern at home and abroad, with the encouragement of multiple government policy, not only the urgent need to achieve energy saving of minimum requirements and the need to find a new breakthrough, achieving a new development of the cement industry. The cement industry is the best way to achieve diversification, namely the use of cement made of sand and gravel aggregate ore, so far, there have been many users into limestone production line, in order to promote the transformation of the cement industry.

By the case of partial cement plant develop gravel aggregate to develop new roads for the cement company can be seen, after crushing limestone can be used as raw material in cement production offer, and can provide high-quality sand and gravel to the construction industry, for the cement factory , development of aggregate regarded as a win-win strategy.

Currently, large quantities of limestone and lime used as building materials, many of the important industrial raw materials, limestone can be directly processed into stone or fired into the quicklime. The cement is obtained by mixing limestone and clay, prepared by high temperature calcination. Because limestone are non-renewable resources, so for the full utilization and conservation of limestone became a major focus of the industry.

Active lime production line is the production activity of lime pipeline operations. Usually the rotary kiln by processing different materials can be divided into cement kiln, metallurgy chemical kiln and lime kiln. Cement kiln is mainly used for calcining cement clinker, sub-dry process cement kilns and wet process cement kiln two categories. Metallurgical and chemical kiln is mainly used in metallurgical industry, steel plants depleted iron ore magnetic roasting; chromium, nickel, iron ore roasting; refractory ore plant calcined high alumina bauxite and aluminum roasting clinker, aluminum hydroxide; chemical chromium ore roasting and chrome ore and other minerals. Lime kiln for firing steel mills, ferroalloy plant with active lime and light burned dolomite.

Lime kiln applications enable the rapid development of the cement industry, its technical parameters, performance and functioning, to a large extent determine the quality, yield and cost of their products.

Active Lime Production Line Process Description

Qualified limestone stored in silos, the Lifting and carried into the preheater at the top of the silo. Preheater top hopper, two upper and lower level meter to control the feed amount, and then blanking tube limestone evenly distributed into the preheater Calvary room. Limestone in the preheater kiln is heated 1150 ° C gas to about 900 ° C, about 30% decomposition, the hydraulic push rod pushed into the rotary kiln, the limestone in the kiln by sintering decomposed into CaO and CO2. After the decomposition of limestone into the cooler in the cooler was bubbled into the cold air cooled to 100 ° C at the discharge. 600 ° C hot air through heat exchange into the kiln and gas co-firing. In the exhaust blended with cold induced draft fan into the baghouse, and then the exhaust fan into the chimney. A lime cooler by vibrating feeder, bucket chain conveyor, bucket elevator, belt conveyor into the lime finished products. According to customer requirements whether screening processes.

Lime Production Line Features:

1. less investment and quick profile.

2. short construction period, low energy consumption.

3. Low cost, high activity products meet environmental emissions.

4. high efficiency, less pollution, rational use of resources.

5. The equipment is simple, easy to design the production line.