Industry Reports

Crushing and Homogenization of Dry Process of Cement Production

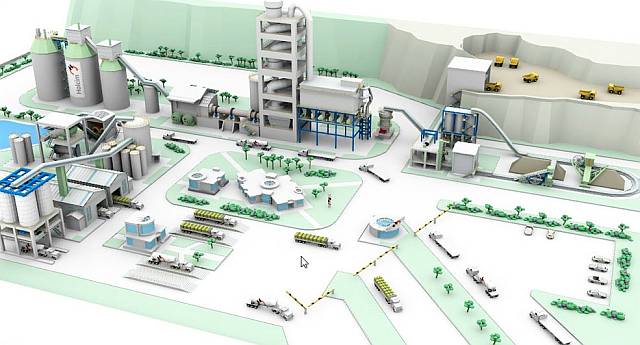

1) Limestone Crushing

During cement production process, most raw material needs to be broken, such as limestone, clay, iron ore and coal, etc. Many cement enterprises generally adopt pre grinding technology. Limestone is the largest raw material, with large particle size after exploration, higher hardness, so limestone crushing occupies more important position in cement factory crushing process.

Crushing process is more economical and convenient than grinding process. The reasonable choice of crushing equipment and grinding equipment is very important. Size of raw material, the smaller the better, before being put into grinding equipment to reduce the load of grinding equipment, and improve mill's production. Materials after broken, can reduce granularity material separation phenomenon in the process of transportation and storage, and it is advantageous to uniform raw ingredients, improve the accuracy of the ingredients.

2) Raw Material Pre Homogenization

Raw material pre homogenization is to achieve initial homogenization, using scientific material piling and taking technology in the storage and fetching process, finally to make the raw material yard and function of storage and homogenization at the same time.

The basic principle of raw material pre homogenization is that: when materials are piled up, the stacker will make raw materials continuously in a certain way into mutual parallel, overlapping and up and down as much as possible to form the same thickness of material layer. When picking up material, it is recommended in the perpendicular direction of the material layer, trying to cut out all the layers at the same time, as far as possible, until the end, namely" flat laying, straight picking".