Company News

Cement production line detailed introduction

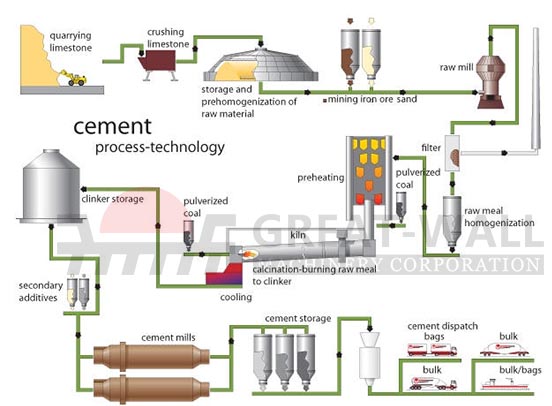

Cement production line includes crushing and pre-homogenization, raw material preparation & homogenization, preheating & decomposition, cement clinker sintering, cement grinding and packaging etc. Great Wall machinery have the ability to built 1000t / d ~ 10000 t /d cement production line independently, And has extensive experience in the design and construction, built many large cement production line, such as the 5000t / d cement production line for Henan Meng Electric-Group and 5000t / d cement production line for Chongqing Jin Jiang. The production line using new dry process cement technology, can reduce power consumption by 20% to 30%, greatly reduce production costs, improve the overall efficiency of enterprises.

Advantages

Cement production line consists of a range of facilities, including raw material preparation, raw material grinding, Raw material homogenization, cement clinker sintering, cement grinding , packaging and transport etc.the equipment of Cement production line include: cement rotary kiln, cyclone preheater, grate cooler etc.

Cement production is a relatively complex physical and chemical processes, with different raw material preparation methods, cement production can be divided into dry (including semi-dry) and wet (including semi-wet method). Dry process is mainly used Today, raw material were preheated by the preheater & exhaust gas before it passed into kiln, and then 90% of Calcium carbonate in the raw material were split into calcium oxide.

[process feature]: raw material crushing, raw material pre-homogenization, raw materials blending, energy efficient grinding of raw material, raw material homogenization, suspension preheater and precalciner, the new type cooler, cement batching and grinding.

[Technical advantages]: cement production with features of high efficiency, high-quality, energy-saving, fully utilizing of resources, Comply with the requirements of environmental protection and sustainable development.

1. Provision of EPC / Turnkey Services

Since 1958 the establishment of factory, we have been engaged in research and development and innovation of cement grinding equipment, nearly 60 years of experience in the market Great Wall Machinery has excellent ability of cement EPC line, from design, building till project completion, truly saving time & effort for customers, Integration of contracting reduce construction cost of the whole project and ensure the quality of EPC line, It is a modern, new type of trading model.

2. The self-developed grinding equipment

Great Wall machinery can produce Various main equipment, including raw material mill,clinker mill, rotary kiln, ball mill.the Mill equipment is safe and reliable, high degree of intelligence, environmental protection, and won several national patents, also used in a number of cement plants in the country.

Henan Meng Electric Group bought a number of cement production line from Great Wall Machinery, including one 5000t/d cement line and three 3000t/d cement line, now they are all running well, and gained excellent economic benefit

Benefit

1. Powerful capacity,high automation

2. low emissions of harmful substances, use a large amount of industrial waste, protect the environment, reduce waste disposal costs.

3. High utilization, profits can be maximized.