Company News

The five operation point of xinxiang Great Wall Machinery vertical mill

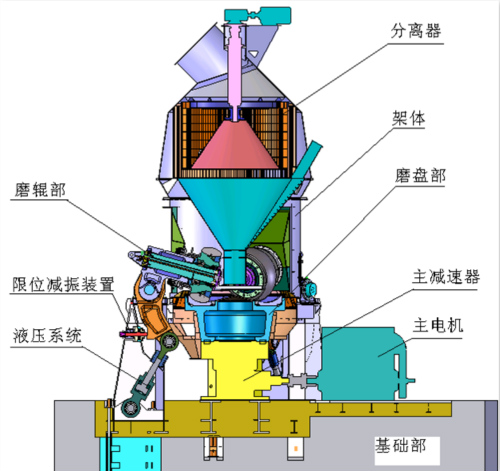

Cement vertical grinding machine, slag vertical grinding machine, vertical grinding machine, nickel slag materials vertical grinding machine, vertical grinding equipment producted by Great Wall Machinery manufacture, as its high grinding efficiency, low power consumption, small dust pollution and other significant characteristics of similar products in the industry has great competitive advantage, and in the cement, mining, power plants and other industries widely used.Below let me intorduce you the reveal the Great Wall machinery vertical roller mill the five operational key points:

1. stability

Stability of the bed material bed, which is the basis of roller abrasive grinding bed, the key of normal operation.Material thickness can be adjusted by the keep-off circles, suitable thickness and corresponding relation between them with the mill production, commissioning stage should be the first to find out.Grinding layer is too thick and material layer is too thin will cause vibration.If roller pressure increase, produces more fine powder, material layer will become thinner;if the roller pressure reducing, mill material coarsening, return material increase, material layer become thick.Ground wind speed increase, increase internal circulation, the material layer thickening, reducing wind speed, reduce internal circulation, the material layer thinning.Under the normal operation of roller mill after roller compaction of the material bed thickness should not be less than 40 ~ 50 ram.

2. control the grinding pressure

Grinding pressure is the main factor affecting grinding machine, grinding machine efficiency and power output.Vertical mill is use the pressure on bed to crush material. With the pressure increase, the production increase. But no longer changes after reach a certain threshold, the increase of the pressure increase followed by power, lead to the increase of unit energy consumption, so the suitable roller should balance the yield and energy consumption.It depends on the material properties, particle size and feed rate.During trial production to find out a suitable grinding pressure and reasonable wind speed to form good internal circulation, make the material layer on the mill proper, stable, high grinding efficiency.In cement plant, when the wind ring area of a certain wind speed is determined by the volume.The corresponding relationship between process and production capacity, to ensure the grinding effect.

3.guarantee of the grinding temperature

Vertical mill is a drying and grinding system, out temperature is the comprehensive index to measure the drying operation.In order to ensure good raw material drying,the final moisture is less than 0.5%, general control mill outlet temperature around 90 ~ C.If the temperature is too low, the finished product’moisture wil be too high, reduce powder grinding efficiency and efficiency, may cause dust collecting system;If too high, it means flue gas temperature and humidification is insufficient, will also affect the effect of dust collecting.

4. reasonable control of the wind speed

Vertical mill mainly circulate by air material.Reasonable wind speed can form good internal circulation, make plate material layer on the proper and stable, high grinding efficiency.But air volume is determined by wind speed, and air velocity associated with feed rate.If feed capacity is large, air volume thrown.The air volume is affected by system resistance.It can be adjusted through the fan to adjust the valve.Pressure drop of mill, grinding into negative pressure, the negative pressure all can reflect the size of the air.

5.control raw meal fineness

Raw meal fineness is influenced by the rotating speed of separator, system air volume, mill load, etc.In the case of constant air volume and load, can be manually change speed to adjust the fineness, adjust the maximum plus or minus 2 r/min,over plus will lead to mill vibration increase even trip.

Great Wall Machinery adhere to the "customer satisfaction is our eternal pursuit of" business philosophy, adhering to the "one-stop service, a window of foreign" service tenet, strictly to ensure product quality, the efforts to improve service levels, to provide design, manufacture, installation, debugging, reaches producing standard turnkey projects.