Industry Knowledge

(ISO 9001 & CE) factory cement rotary kiln price

Introduction of cement rotary kiln

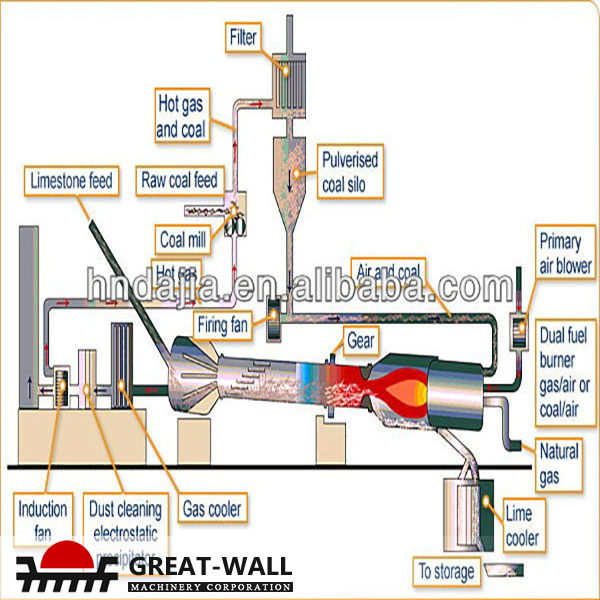

Cement rotary kiln, which is mainly used for calcinating cement clinker, is the main equipment of the new dry type cement production line. This equipment is mainly composed of cylinder, supporting device, supporting device with catch wheel, transmission device, lubrication device, mobile kiln head and sealing device at the end of the kiln.

Working principle cement rotary kiln

Cement raw material is fed into the upper end of the kiln. As the kiln is rotated, the material moves slowly down the kiln through a calcining zone and then a clinkering zone, and is thereafter discharged through the discharge end of the kiln into a cooler.

Fuel is injected into the kiln from its lower end. As the fuel is burned in the kiln chamber, a large amount of heat is produced to sinter the limestone and clay. As hot air keeps rising along the kiln chamber, it ends up being emitted to the atmosphere via the air chimney.

Data of cement rotary kiln

| Model | Output (t/d) | Main Drive (r/min) | Motor (kW) | Regulating Range (r/min) | Gearbox Velocity Ratio | Weight (t) |

| Φ2.2×50 | 96 | 0.125-1.25 | 30 | 132-1320 | 157 | 130.71 |

| Φ2.5×50 | 130 | 0.516-1.549 | 55 | 440-1320 | 99.96 | 167.5 |

| Φ3×48 | 850 | 0.3309-3.309 | 90 | 100-1000 | 32.11 | 237 |

| Φ3.2×48 | 1000 | 0.375-3.75 | 160 | 100-1000 | 27.469 | 252 |

| Φ3.2×50 | 1200 | 0.398-3.975 | 190 | 150-1500 | 40.85 | 263 |

| Φ3.3×52 | 1200 | 0.391-3.91 | 190 | 100-1000 | 27.707 | 280.8 |

| Φ4×60 | 2500 | 0.396-3.96 | 315 | 100-1000 | 34.601 | 487.5 |

| Φ4.2×60 | 2800 | 0.4165-4.165 | 420 | 100-1000 | 35.526 | 576.1 |

| Φ4.3×62 | 3000 | 0.398-3.98 | 420 | 100-1000 | 35.714 | 598.5 |

| Φ4.3×64 | 3200 | 0.449~4.49 | 450 | 100~1000 | 24.365 | 585 |

| Φ4.5×66 | 4000 | 0.41~4.1 | 630 | 100~1000 | 34.069 | 710.4 |

| Φ4.8×70 | 5000~5500 | 0.4~4.0 | 630 | 100-1000 | 30.876 | 845.3 |

| Φ4.8×72 | 5000 | 0.403~4.03 | 560 | 100~1000 | 30.365 | 847 |

| Φ4.8×74 | 5000 | 0.35~4 | 630 | 130~1500 | 42.226 | 841 |

Product advantage of cement rotary kiln

1.Supporting device: advanced shaft structure, automatic temperature measuring device and electrical heating.

2.Catch wheel: including two kinds mechanical wheel and hydraulic pressure.

3.Gears: single or double. Control the rotating speed by buncher, DE machine and frequency variable motor. Be reliable, energy-saving, and efficient.

4.Cylinder type bolster: lower bolster has three types: fixed, zoom and floating. The structure is simple, replacement is convenient and won鈥檛 hurt cylinder.

5.Sealing equipment: there are many kinds for choice according to kiln models, including air cylinder edge sealing, spring edge sealing, and graphite block sealing and combination for above. The sealing effect is very good.

6.Kiln head hood: including stationary type and flexible type.

Company Information

Xinxiang Great Wall Machinery Corporation covering an area of 330,000 m² and having more than 1,100 employees, the company has a total asset of CNY 500 million and has passed ISO9001:2008 quality management system authentication and is a main specialized supplier for manufacturing large scale kiln mill. Possessing the experience of equipment manufacturing for more than half a century, the Company has formed the perfect operation and management system in design and development, product manufacturing, market promotion, equipment installation and after sales service. The Company once won the honors of High Growth Private Enterprise of Henan Province, The Top 100 Suppliers of China’s Cement Industry in 2012, The Top 10 Innovative Enterprise of China’s Cement Industry in 2012 and so on.