Industry Knowledge

China Manufacturer for Rotary Cement Kiln

Introduction of Rotary cement kiln

Rotary cement kiln is composed of cylinder, gears, support device, kiln liner and kiln tail sealing equipment, kiln head hood and fuel device.As a heated pivoting part, cylinder is made of highquality carbon steel plate and supported on the support device by wheel belt. There is mechanical or hydraulic pressure catch wheel on the first or several support device in order to control the turning of cylinder. Gears make cylinder rotate according to process required rotating speed through the ring gear in the middle of cylinder. Because of the need of installation or maintenance, the bigger rotary kiln has auxiliary rotary gears, which makes cylinder gyrate more slowly. To prevent enter of cold air and dust overflow, the reliable kiln tail and head sealing equipment are installed on feed and discharge end.

Advantage of rotary cement kiln

1. The Cement Rotary kiln is an inclined rotary cylinder, the raw material enter the cylinder through the high end of the machine,then move in with the movement of of the rotary kiln. Therefore, the rotary kiln is a conveying equipment.

2. Rotary kiln is a combustion device.

3. Rotary kiln has the function of heat exchange.

4. Rotary kiln has the chemical reaction function.

5. The rotary kiln has the function of degrading and re-using the waste.

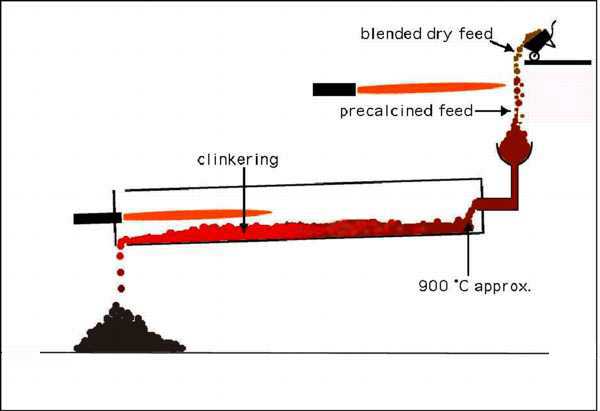

Working principle cement rotary kiln

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards them lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process aterial (cocurrent), but usually in the opposite direction (countercurrent). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burnerpipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil or pulverized coal.

Date Of Rotary Cement Kiln

| Model | Output (t/d) | Main Drive (r/min) | Motor (kW) | Regulating Range (r/min) | Gearbox Velocity Ratio | Weight (t) |

| Φ2.2×50 | 96 | 0.125-1.25 | 30 | 132-1320 | 157 | 130.71 |

| Φ2.5×50 | 130 | 0.516-1.549 | 55 | 440-1320 | 99.96 | 167.5 |

| Φ3×48 | 850 | 0.3309-3.309 | 90 | 100-1000 | 32.11 | 237 |

| Φ3.2×48 | 1000 | 0.375-3.75 | 160 | 100-1000 | 27.469 | 252 |

| Φ3.2×50 | 1200 | 0.398-3.975 | 190 | 150-1500 | 40.85 | 263 |

| Φ3.3×52 | 1200 | 0.391-3.91 | 190 | 100-1000 | 27.707 | 280.8 |

| Φ4×60 | 2500 | 0.396-3.96 | 315 | 100-1000 | 34.601 | 487.5 |

| Φ4.2×60 | 2800 | 0.4165-4.165 | 420 | 100-1000 | 35.526 | 576.1 |

| Φ4.3×62 | 3000 | 0.398-3.98 | 420 | 100-1000 | 35.714 | 598.5 |

| Φ4.3×64 | 3200 | 0.449~4.49 | 450 | 100~1000 | 24.365 | 585 |

| Φ4.5×66 | 4000 | 0.41~4.1 | 630 | 100~1000 | 34.069 | 710.4 |

| Φ4.8×70 | 5000~5500 | 0.4~4.0 | 630 | 100-1000 | 30.876 | 845.3 |

| Φ4.8×72 | 5000 | 0.403~4.03 | 560 | 100~1000 | 30.365 | 847 |

| Φ4.8×74 | 5000 | 0.35~4 | 630 | 130~1500 | 42.226 | 841 |

Packaging & shipping

Before sales: Guide customer to choose the most suitable type of equipments; provide advanced, energy-saving and practical flow chart as well as responsible for designing the whole schem.

On sales: Inspect the product seriously before out of the factory; Invite customer for commissioning in the spot and raising the objection:Organize to delivery according to the contract.

After sales: Company can send technical persons for guiding to install ,debugg and train the workers.

Our Services

Installation and adjustment of ball mill: The installation of our ball mill is needed. Technicist of ball mill will provided by supplier for buyer to assist the work such as weding connection of shell body, equipment installation, adjustment, training, etc.

Quality Guarantee of ball mill: Three-guarantees of ball mill and warrantly period is one year.

Technical support of ball mill is provided from the beginning to the end.

Spare parts of ball mill are serviced for sale in the whole year.

Company Information

Xinxiang Great Wall Machienry Corporation, establelished in 1958, is one of the biggest Xinxiang Great Wall Casting Co., Ltd .Rotary cement kiln manufacture and supplier in Henan Province of China.Total area of the factory is 330000 m2, over 1100 employees including technicians.The annual processing capacity is over 80000 ton. Besides, we have a self-governed casting subsidiary, Xinxiang Great Wall Casting Co., Ltd, whose annual output is up to 50000 ton. That’s why we can supply you the best quality machinery with less lead time.

The main products are:

GRM series raw material vertical mill, cement mill that can cater to below 10000t/d cement production line, and the series slag vertical mills with annual production capacity of 0.3 million ton, 0.6 million ton and 1.0 million ton.

Φ4.8m×74m,Φ4.5m×66m,Φ4.3m×66m,Φ4.2m×60m series of NSP rotary kiln

Φ4.2m×13m cement grinding mill and other ball mills

Rod mill and trellis pattern overflow mill for coal chemical industry and alumina industry; and the relevant supporting equipments for cement production lines.

FAQ

How about the quality of your ball mill?

Our ball mill manufactured strictly accordin to national and international standard.

We take a test on every ball mill before delivery.

How about price of ball mill?

We can give the lowest price of the ball mill than market one.

We do quotation of ball mill as soon as possible for any custome.

Discount of ball mill can be given according to quantity.

How about the after-sale service of your company?

Our engineer is aviliable to installation ball mill overseas.

The guarantee period of our ball mill is one year.