Industry Knowledge

lime rotary kiln with competitive price

Introduction of Lime Rotary Kiln:

Lime rotary kiln is the main equipment of lime production line. It is widely used for many industries like metallurgy, chemical industry, building refractory materials, environmental protection, etc. The rotary kiln consists of cylindrical shell, supporting device, supporting device of thrust roller, driving unit, moveable kiln head, sealing device on the tail of kiln, coal dust pipe device, etc., the kiln body has a certain tilt angle with level. The whole kiln body is supported by the roller supporting device, and it is also equipped with thrust roller device to control the up and down movement of the kiln body.

Features of lime rotary kiln:

High Automation Level

The lime rotary kiln is with advanced structure. Its pre-heater with low-pressure loss can improve preheating effect efficiently. After preheating, the resolution ratio of the lime-stones can reach 20~25% when they enter the kiln. Besides, the lime-stones, with fine fraction about 10~15mm, can be used directly.

Waste Heat be Reused Effectively

The two sides of the reliable rotary kiln are sealed by the combined scales, which can make the air leakage coefficient less than 10%. Composite refractory materials should be used in order to reduce the loss of radiant heat.

Low Energy Consumption

The filling vertical cooler, round or square, can be zoned-ventilation, which can make the temperature of lime-stones in the cooler at about 80°C. As a result, it is very convenient to transport and store. It can also pre-heater the secondary air up to the temperature above 700°C, then the waste heat can be recycled to reduce energy consumption.

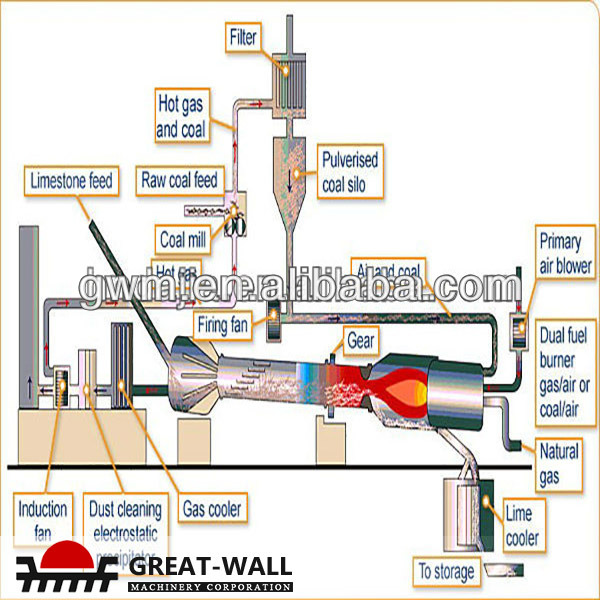

Working Principle of Lime Rotary Kiln:

The economical Rotary kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material grad-ually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (cocurrent), but usually in the opposite direction (countercurrent). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burnerpipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil or pulverized coal.

technic parameter:

| Model | Output (t/d) | Main Drive (r/min) | Motor (kW) | Regulating Range (r/min) | Gearbox Velocity Ratio | Weight (t) |

| Φ2.2×50 | 96 | 0.125-1.25 | 30 | 132-1320 | 157 | 130.71 |

| Φ2.5×50 | 130 | 0.516-1.549 | 55 | 440-1320 | 99.96 | 167.5 |

| Φ3×48 | 850 | 0.3309-3.309 | 90 | 100-1000 | 32.11 | 237 |

| Φ3.2×48 | 1000 | 0.375-3.75 | 160 | 100-1000 | 27.469 | 252 |

| Φ3.2×50 | 1200 | 0.398-3.975 | 190 | 150-1500 | 40.85 | 263 |

| Φ3.3×52 | 1200 | 0.391-3.91 | 190 | 100-1000 | 27.707 | 280.8 |

| Φ4×60 | 2500 | 0.396-3.96 | 315 | 100-1000 | 34.601 | 487.5 |

| Φ4.2×60 | 2800 | 0.4165-4.165 | 420 | 100-1000 | 35.526 | 576.1 |

| Φ4.3×62 | 3000 | 0.398-3.98 | 420 | 100-1000 | 35.714 | 598.5 |

| Φ4.3×64 | 3200 | 0.449~4.49 | 450 | 100~1000 | 24.365 | 585 |

| Φ4.5×66 | 4000 | 0.41~4.1 | 630 | 100~1000 | 34.069 | 710.4 |

| Φ4.8×70 | 5000~5500 | 0.4~4.0 | 630 | 100-1000 | 30.876 | 845.3 |

| Φ4.8×72 | 5000 | 0.403~4.03 | 560 | 100~1000 | 30.365 | 847 |

| Φ4.8×74 | 5000 | 0.35~4 | 630 | 130~1500 | 42.226 | 841 |

About us:

Our services:

1. Pre-sale Services:

1). Select proper equipment model;

2).Design and manufacture products according to clients' special requirement;

3). Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1).Make sure goods prepared within delivery time;

2).Pre-check and accept products ahead of delivery;

3).Prepare documents required to help customer pass customs clearance.

4). Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sale Services:

1). Assist clients to prepare for the first construction scheme;

2). Install, debug and examine the equipment;

3). Train technical personnel the first-line operators;

4). Provide technical exchanging

5). Offer spare parts at a best price for long term.

FAQ:

How Is Your Products?

we always keep the policy of "quality first, integrity based". Our products have won national and international quality certificate and all kinds of national honor certificates. Every equipment will be tested before delivery.

How Is Product's price?

we are factory and we can give you the lowest price than the market. our sales goal is not only earn the money but also know more clients to develop the further cooperation. we also could adjust product's price based on your purchasing quantity.

Product's warranty:

If the products can't work normally as our product's describe and promise. we will send the technicians to your working site or 100% refund.