Industry Knowledge

Great-Wall Vertical Mill for raw grinding

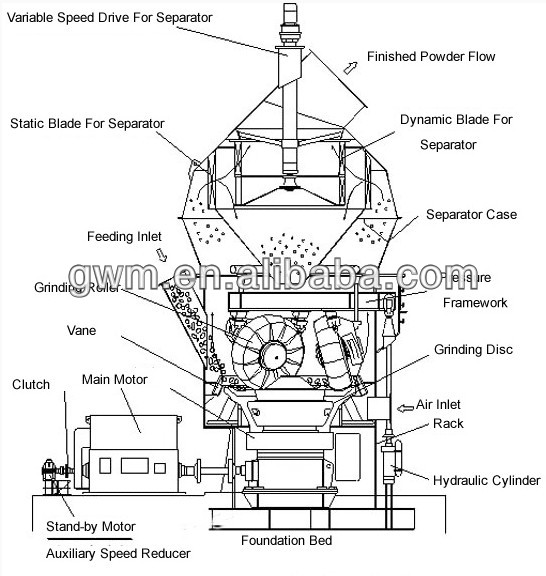

Description of Vertical Mill for raw grinding:

Vertical Mill for raw grinding is a type of industrial equipment used to crush or grind materials into small particles. Vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materials.

Structure features of Vertical Mill for raw grinding:

1.High-performance separator and optimised airflow ensure high separation efficiency and low pressure loss for energy saving.

2.Unusually large rollers permit coarse feed and ensure a thick grinding bed for maximum uptime.

3.All impact forces and dynamic reactions are small and vertical therefore easy to accommodate – prevents mill stops.

4.Segmented wear parts for table and rollers allow use of the most wear-resistant materials and hardfacing for long life.

5.Reversible roller segments ensure high material utilisation. External circulation limits power consumption of fan.

6.Feed sluice ensures low false air flow and steady feed flow for minimum power consumption and optimum mill production.

7.The raw mill is easily adaptable to high airflow required by especially wet easy to grind materials.

Work Principle of Vertical Mill for raw grinding:

Raw material feed into discharege pipe through rotary discharger. Discharge pipe enter into the mill through the side or the center of separator. Material will fall into the center of mill disc with the help of gravity and air flow. Mill disc connect with the reducer constantly. Constant speed rotation of mill disc will distribute materiao evenly in the lining plate of mill disc. There inclined mill roller will be bite material and pulverize. Grind material with the function of pressure and friction. Centrifugal force will make pulverized material at the edge of mill disc from the middle of mill disc. Material off mill disc will enter into hot gas in the mill through air ring. Via the middle of the mill shell and enter into the separator. During the process, material will exchange hot gas. The moisture will be evaporated. The rest moisture can reach 1%. Unpulverized material as request will be selected by the separator and send back vertical raw mill disc.

Technical Parameters:

| Model | Grinding Table Diameter (mm) | Roller Diameter (mm) | Roller Number (n) | Motor (kW) | Output (t/h) |

|---|---|---|---|---|---|

| GRMR22.30 | 2200 | 1400 | 3 | 550 | 70 |

| GRMR26.30 | 2600 | 1600 | 3 | 790 | 100 |

| GRMR28.30 | 2800 | 1750 | 3 | 900 | 115 |

| GRMR30.30 | 3000 | 1700 | 3 | 1000 | 120 |

| GRMR32.30 | 3200 | 1500 | 3 | 1400 | 160 |

| GRMR34.30 | 3400 | 1500 | 3 | 1600 | 180 |

| GRMR36.41 | 3600 | 1600 | 4 | 1800 | 200 |

| GRMR38.41 | 3800 | 1700 | 4 | 1900 | 230 |

| GRMR40.41 | 4000 | 1800 | 4 | 2240 | 260 |

| GRMR43.41 | 4300 | 1900 | 4 | 2500 | 310 |

| GRMR46.41 | 4600 | 2060 | 4 | 3150 | 350 |

| GRMR48.41 | 4800 | 2240 | 4 | 3350 | 390 |

| GRMR50.41 | 5000 | 2360 | 4 | 3500 | 420 |

| GRMR53.41 | 5300 | 2500 | 4 | 3800 | 470 |

| GRMR56.41 | 5600 | 2600 | 4 | 4500 | 540 |

| GRMR59.61 | 5900 | 2600 | 6 | 5000 | 610 |

| GRMR63.61 | 6300 | 2700 | 6 | 6000 | 720 |

About us:

FAQ:

1 how long is the product warranty period ?

A: the product warranty period is 12 months

2. I am a foreign customers, if the machine works wrong, how your company resolved ?

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

3. how much is MOQ of your machine?

A:our machines MOQ is 1 set and also support the mixed batch.

4.Where can we buy the machine's parts?

A: Our company can provide machines for your any time.