Industry Reports

It is must use the main equipment of vertical roller mill in the industrial waste production line?

In recent years, with the continuous development of industrial production. The development of grinding equipment from ball mill + roller press to vertical roller mill equipment, which has also undergone historic reforms.

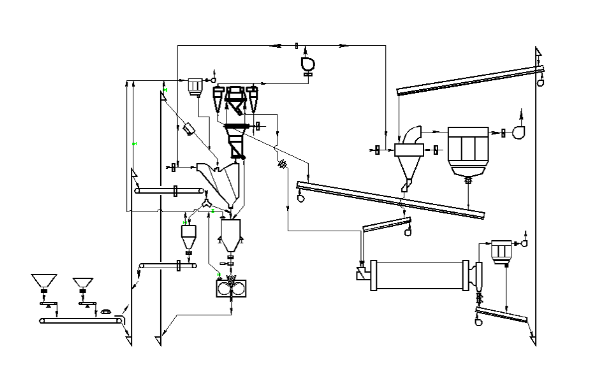

The traditional ball mill + roller press is more complicated in the comparison of the vertical roller mill. The main body of the whole system is composed of multi-layer frame buildings, the equipment is distributed between the frames of each layer, and the equipment connecting pipes pass through the frames of each layer. At the same time, the dust is large, the area is up, and the noise is large. Not suitable for raw materials with high moisture content, the quality is difficult to control.

The replacement of the vertical mill grinding equipment has made a huge change in the process system. The vertical mill equipment integrating grinding, conveying, powder selection and drying, it greatly saves the floor space, and the closed production space system also reduces noise and reduces dust pollution. For a variety of materials have different parameter settings, the material is easier to adjust.

In the system operation rate, the roller press + ball mill system has a high shutdown rate, the online surfacing has a long time, and the system operation rate is low. The vertical mill equipment has a very low downtime, and the online butt welding time period has a high system operation rate.

The times are constantly evolving, and the progress in the production of vertical mill equipment is just beginning. chaeng strives to be the “heritor and promoter of vertical mill”, focusing on the production of vertical mills, which makes industrial waste slag grinding production achieve better results.