Industry Reports

Great Wall Machinery: slag vertical mill EPC production line is to energy saving and environmental protection

In the grinding equipment, vertical mill is the representative of energy saving and environmental protection, but the vertical mill energy saving does not mean that its total EPC production line can be energy-saving environmental protection, need to be done in all aspects of energy saving and environmental protection.

The Chaeng (Great Wall Machinery) Vertical Mill Production Line Energy Saving Case:

Annual output of 600,000 tons slag production line in Hebei Aosen Iron and Steel Plant

This slag powder production line compared with other slag production line has two prominent advantages:

First, slag raw materials shipped directly from their own steel plant to use, eliminating the slag a large number of transportation costs and purchase costs, but also a good iron and steel plant emissions of industrial waste secondary use, to achieve cycle development.

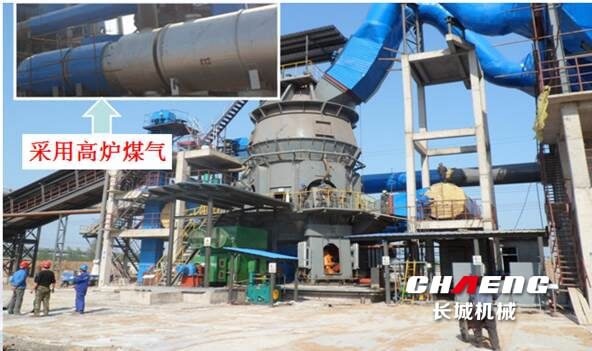

Figure: slag powder production line using their own emissions from the Austrian Iron and Steel Plant blast furnace gas

Figure: Fine layout of the blast furnace gas pipeline

Second, the hot air furnace fuel is not a common coal, but the use of their own steel plant emissions of blast furnace gas to solve the blast furnace gas pollution of the environment, but also to achieve the recycling of waste gas, greatly reducing energy costs.

Chaeng Vertical Mill EPC Production Line Environmental Protection Case:

Chaeng annual output of 600,000 tons slag powder model production line:

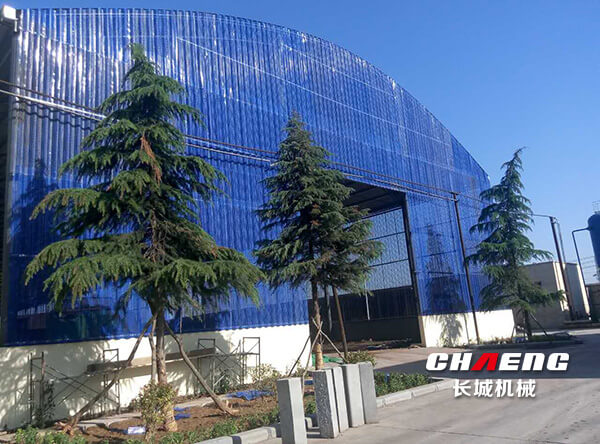

Improved one: raw material yard full closed environmental protection design

The original material duet open-air design, dust pollution is very serious. In response to national environmental policy, the Great Wall Machinery has established a fully enclosed environmental protection yard environmental protection shed. Will be isolated from the dust pollution in the greenhouse, reducing environmental pollution.

Improved two: the host device for color transformation

The company will also from the 'technology, quality, cost, service' four aspects of the full realization of the upgrading, the use of the new color of the new upgrade, it’s Chaeng adhering to the 'good blue sky, from the Great Wall made' concept of comprehensive reflection and practice, A meticulous manufacturing process, the pursuit of excellence in the spirit of enterprise, will create a world-class high-end equipment manufacturing brand.

In the nickel slag production line equipment for the first time the use of environmentally friendly lake blue measures, the industry was well received. Began in the slag powder demonstration line for improvement.