Industry Reports

Comparison of Chaeng vertical roller Mill and Raymond Mill

1. Vertical mill system of advanced technology:

a.Vertical mill can be used outside the loop process, the system more energy-saving, labor-intensive workers. Raymond Mill can not be used outside the loop process.

B. The position of the main motor, air inlet, outlet, inlet and outlet can be adjusted according to the position of the process. The feeding way can save the project investment by side feed or top side feed according to the raw material moisture. Mongolia grinding can not do such a change.

C. Vertical roller mill can achieve mass production, low energy consumption, high efficiency, suitable for large-scale enterprises, modern; Raymond Mill specifications, low productivity, high energy consumption (than vertical mill unit power consumption higher than 20 ~ 50%), can not achieve the scale of business.

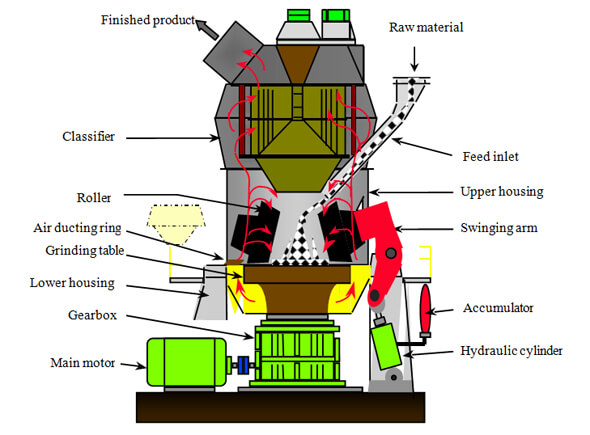

2. Equipment structure:

Vertical grinding mill adopts hydraulic pressure mechanism, roller roll turning mechanism is borrowed from German loesche company LM type vertical mill structure, which can be light load start and easy maintenance. Working time, the roller pressure can be run in accordance with mill status in the control room to adjust. Raymond mill with pendulum structure, by centrifugal force, not only can not control the pressure is small.

B. Vertical mill roller shell, lining with alloy casting or composite surfacing, on-line surfacing, and the German company Leslie LM vertical mill similar to improve the wear-resistant material utilization. General roller shell, lining life of 10,000 hours or so. The Raymond mill roll shell, grinding ring with high manganese steel material, life expectancy is only about 2000 hours.

C. Vertical grinding roller bearings Sealed according to the size of the model can be sealed fan can also be used simple and reliable mechanical seal, can be used for cooling oil lubrication cycle, greatly improving the bearing life. Raymond Mill can not use a reliable seal, the bearings in the grinding chamber is easy to dust, high failure rate, short life.

D. Compared with Raymond mill, vertical grinding mill without grinding body direct contact with the phenomenon, the equipment is more stable operation, the preparation of coal powder is more safe and energy saving. Raymond mill with pendulum by centrifugal force, can not avoid the roller, ring collided with the situation, noise, for pulverized coal, can not avoid the production of Mars, an increase of insecurity. The vertical mill adopts the special vertical reducer transmission, the transmission efficiency is high, the service life is long (more than 10 years); Raymond mill uses the pulley or the worm gear transmission, its transmission efficiency is low, the failure rate is high, the life is short (about 2 years Need to be replaced).

3. maintain:

Vertical mill replacement roller shell, lining can be used when the repair cylinder roller grinding mill out of the shell outside, while 2-3 face can work at the same time, easy to focus on the use of limited owners of human and material resources. Generally about 8 to 24 hours to complete.

B. Raymond grinding mill maintenance, the mill almost all apart, labor-intensive, long time, generally takes 3-5 days to complete. The roller, grinding ring, scraper, etc., about 3 months to be replaced, spare parts costs high.

4. Production operations:

Vertical mill operation High degree of automation, can be light-load start, without pre-grinding the fabric, not because of instability within the material layer within the boot failed to start in a short time the second start. When the system appears a short time fault such as broken material when the mill can be lifted to wait for troubleshooting after the production.

B. Raymond mill operation low degree of automation, mill vibration, can not be effective automatic control. Multiple mills need to be equipped with the corresponding operator, resulting in low labor efficiency, high labor costs.

C. Raymond mill can not dry continuous milling, because the roller assembly is the use of grease in the bearing assembly, must be manually every one to two classes to stop filling grease once. Vertical grinding roller bearings used in oil lubrication forced lubrication, continuous operation can be achieved production, automatic lubrication.