Industry Reports

Introduction of Chaeng Lime Production Line Process Equipment

Lime is the most basic raw materials in the construction industry, has a broad market prospects. Lime can not only be used to produce all kinds of lime slabs, lime sand bricks, fly ash bricks, concrete aerated blocks, can also have a certain activity of materials (such as granulated blast furnace slag, fly ash, coal gangue slag Industrial residue), according to the appropriate proportion and lime with the common grinding, can be obtained with a certain activity of the cementing material, that is, clinker-free cement.

With the improvement of lime production process, the traditional old kiln, soil burning lime kiln pollution, poor quality, low production capacity, has been eliminated. Great Wall Machinery introduced the international advanced automatic calcination technology, has introduced a modern energy-saving, environmental protection and efficient white lime production line , not only in line with national environmental requirements, and the production of lime products of high quality, high activity by the current domestic hundreds of thousands Lime production line business recognition.

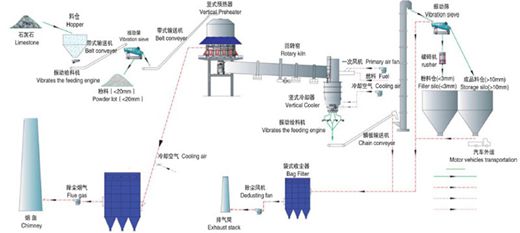

Process flow and equipment analysis of lime production line

Figure: Lime production process flow chart

The production process is: limestone stored in the silo, from the upper and lower level control of the feeding amount of two materials, and then through the feed pipe to the limestone evenly distributed to the preheater room, in the process, the limestone in the preheating Furnace by 1150 degrees Celsius kiln flue gas heated to about 900 degrees Celsius, about 30% decomposition, and then pushed into the rotary kiln by the hydraulic putter, the limestone in the rotary kiln chemical reaction, the calcination decomposition of CaO and CO2; Lime into the cooler, cooler in the drum into the cold air cooled to 100 degrees Celsius below discharge. The heat exchange of 600 degrees Celsius hot air into the kiln and gas mixture fuel. Exhaust gas and then into the cold wind by the fan into the bag filter, and then discharged into the chimney by the exhaust fan, the cooler lime by vibration feeder, bucket elevator, belt conveyors and other equipment into the lime storage.

According to user needs to determine whether the screening process. In the whole lime calcination system, the preheater is divided into several preheating chambers according to the different output. Each preheating chamber is equipped with a hydraulic pushing device and equipped with an automatic control system to transfer the relevant data to the PLC control platform of the central control room , To achieve centralized control.

Chaeng(Great Wall machinery) lime production line to limestone, coal (or blast furnace gas as raw materials), What’s the system's main equipment ?

1, calcination system include: firing kiln tail, firing kiln, firing kiln head. The calcination system apparatus comprises:

Vertical preheater ---- bear limestone heat transfer and 30% decomposition of calcium carbonate task.

Rotary kiln - bear the remaining part of the decomposition task. Under the same conditions, the Great Wall machinery rotary kiln production of lime activity than gas kiln, the average high 30ml or more, the activity is generally 340 ~ 380ml, or even up to 400ml.

Vertical cooling machine ---- bear the finished product cooling and heat recovery tasks.

2, the Great Wall machinery coal pulverizer preparation for escort

Pulverized coal preparation is mainly for the clinker calcination to provide high quality pulverized coal, the Great Wall machinery coal mill is divided into ball mill system and vertical mill system, vertical mill system and ball mill compared to a small footprint, simple installation, low power consumption, noise Small and so on.