Industry Reports

Water slag process new analytical, steel plant industrial waste slag turning waste into treasure

Today we deal with these questions about the water slag- CHAENG(Great Wall Machinery Co.,) experts answer:

1, what is water slag?

water slag with our lives, water slag is waste slag melt state high rapid cooling in water after the past are abandoned, not only pollutes the environment, and gave a large steel plant acquired a processing fee. At present, after the adoption of slag mill processing, slag powder was able to act as a secondary raw concrete and cement to be used.

2, water slag used in cement industry

Now mostly use limestone cement industry to do material processing, but after the limestone resources overexploitation, costs have increased, in order to reduce the cost of cement production and processing enterprises, are now have wars in other alternative resources, slag entered the people sight.

It is reported that slag has potential hydraulic cementitious properties after the slag has been grinding in preparation of the cement clinker, lime, gypsum and other excitation can be used as raw materials to produce high-quality cement slag Portland cement, slag cement plaster , lime slag cement, slag brick, cinder concrete.

3, water slag used in concrete

Slag powder as a mineral admixture of concrete, can be replaced by an equivalent amount of cement, ready-mixed concrete directly in the mixing, depending on the activity and different specific surface area, according to a certain percentage of the incorporation of slag concrete powder, performance significantly improved.

Its performance is:

1), the initial stirring easy to control the rheology of concrete, improve the flow of concrete, good pumping performance;

2), lower heat of hydration;

3), to reduce the demand for cement in concrete, increase the late strength of concrete;

4), sulfate resistance and strong, because the concrete mixing slag powder in C3A content decreased. Accordingly, when hydration reduced Ca (OH) 2 content, thus increasing the sulfate resistance;

5), alkali aggregate reaction;

6), anti-miniature, combined with strong and reinforced.

Therefore, slag powder is particularly suitable for special projects rise buildings, dams, airports, underground and underwater construction.

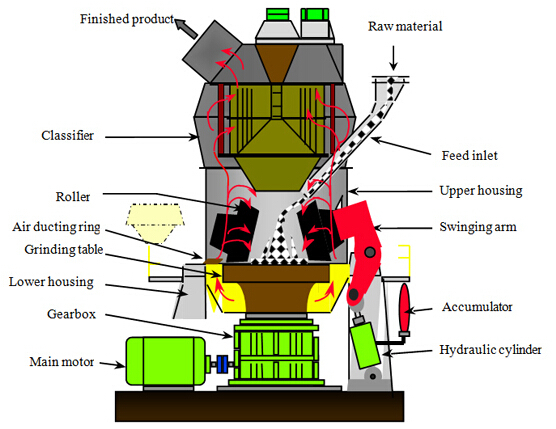

Detailed explanation of the CHAENG of mechanical experts, surely we have a new awareness of the slag, slag powder effect. CHAENG respond positively to the call of the national energy conservation policy, after more than ten years of active cooperation with domestic and foreign research and manufacturing vertical mill senior experts and research institutes to develop a significant energy-saving, low-carbon products GRMS series vertical mill slag machine.

4, the CHAENG new slag grinding mill help steel plant to process industrial waste slag

So with 50 years of experience in manufacturing slag grinding equipment, the CHAENG GRMS series slag roller mill exactly what advantage?

1), low investment costs, strong environmental protection

The slag vertical grinding mill collection, drying, separator in one system is simple, compact layout, small footprint, and can open layout, a large number of lower investment costs. The entire line dust sealing, grinding system working under negative pressure, no dust spills, clean environment, to meet the national environmental protection requirements.

2), low running costs

2.1.High milling efficiency, low energy consumption: the use of roller compacted ground directly on the disc material, low energy consumption, compared with traditional ball mill, the system power consumption savings of 20% -50%.

2.2 post-maintenance costs less: since the roller does not work in direct contact with the disc and the roller and liner wear-resistant material made of high quality, it has a long life, less wear and tear.

3). Strong drying capacity

The use of hot air conveying the material in the mill grinding material moisture can dry up to 15%, eliminating the need for raw material drying systems, and by adjusting the temperature of hot air, the humidity of materials to meet different requirements.

4). Simple operation and maintenance and reliable operation

(1) equipped with an automatic control system, which enables remote control, easy to operate.

(2) with dosing machine, auto-sensing uniform feeding, avoiding the damage to the machine caused by feeding uneven.

(3) through the cylinder inspection, flip rocker replace the roller sleeve, liner, convenient and reduce downtime.

5). Product quality and stability

As the material in the mill residence time is short, easy to detect and control the product particle size and chemical composition, reduce duplication of milling, stable product quality.

Saving energy and solid waste utilization is the greatest significance of slag grinding equipment and technology where research, development space is very large, the future CHAENG will continue to promote slag grinding technology to become a professional, large-scale, brand of direction.