Industry Reports

GRMS Nickel slag vertical mill grinding process technology and principles

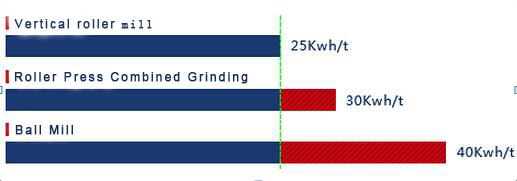

Nickel slag, Blast furnace slag, steel slag grinding process technology, mainly combined ball mill + roller press, pre-grinding roller mill + ball mill grinding, vertical mill grinding. Wherein, GRMS Nickel slag vertical mill grinding process is simple, small footprint, low construction costs, high grinding efficiency,low energy consumption, is the ideal nickel slag, slag, steel slag treatment process.

Slag, steel slag, nickel slag vertical mill works principle as follows: Nickel slag vertical mill uses two forms of feeding and side feeding centers, vertical mill material from falling into the upper lock valve, slide along the feeding tube straight into the disc on, with the rotation of the disc outward throw, again cutting the vertical scraper means Chute welding scraping, he was thrown into the grinding zone lining on the disc, abrasive surface grinding roll grinding in this region Directly above.

On the disc are roller grinding material, by a small portion of the new material with high moisture and most over-the-mill finished with lower water composition. This is because a large part of the unfinished coarse material separated by the separator is returned, which is the recycle material. The slag discharge auxiliary roller compaction. Main roller rocker arm fixed to the main, a good material layer is configured by pressure grinding. Force by the roller itself weight and hydraulic system pressure generated by the roller and the grind bed friction rotation.

Sensors and buffers for the rocker arm roller installed to prevent direct metallic contact with the disc. Was milled slag particles under the effect of centrifugal force is thrown out and through the ring gauge, where it is the collector loop through the wind increased airflow. Dust and gas mixture flows through the grinding chamber, which was equipped with a vertical mill liner wear of the cylinder surrounded enter welded to the vertical mill separator barrel on the finished separator will be elected.

Through the annular air ring by a vertical mill discharge foreign matters, as well as in case of motility disorders, falls through the annular air ring roller mill cone slag grinding, by installing the disc following board scraper, scrape drain mouth after both the nickel slag discharged from here through the air box into the recycle feed tube slide, grinding again, separator, until a qualified products.

CHAENG(Great Wall Machinery) Nickel slag production line project has been officially launched, can be designed to provide customers with an annual output of 30,0000 to 100,0000 t of nickel slag vertical mill production line.