Industry Reports

Vertical roller mill technology

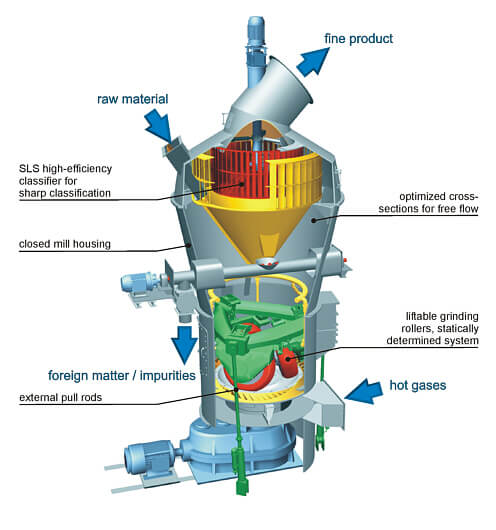

Clearly It's crucial role to know the role of product components. It's better for us to pick the desired product, understand the advantages of vertical mill technology easy to play its role in the using. So, what's the advantage? Let Chaeng(Great Wall machinery) tell you.

1. reducing production investment costs significantly

Vertical mill system process is simple, compact layout, small floor area, covering about 70% of ball mill system, building space of about 60% milling system and may open layout, directly reduce investment costs. And vertical mill separator itself, does not require additional separator and lifting equipment. The grinding dust and gas can be directly collected by the bag filter or electrostatic precipitator.

2. High production efficiency, energy saving and environmental protection

Vertical grinding mill uses the principle of grinding material layer material, low energy consumption, grinding system power consumption by 20% to 30% over the ball, and with the increase of raw water, energy-saving effect is more obvious. Vertical mill and milling system energy systems compared to savings of 30% to 40%. Stand mill did not work in a ball mill balls collide, the impact liner metal crash, so the noise is small, less than the ball 20 ~ 25dB. In addition, vertical mill fully enclosed system, the system working under negative pressure, no dust, clean environment.

3. Strong material drying capacity

vertical mill adapt the hot air transportation of materials, when grinding materials with large water inlet temperature can be controlled, so that products meet the required final moisture. In the vertical mill, can dry - grinding into the grinding material moisture up to 15% to 20%.

4. Simple operation, easy maintenance

Equipped with automatic control system, which enables remote control, easy to operate; through the maintenance tank, turn rotating arm can be quick and easy to replace the roller sleeve, liner, reduce business downtime.

5. Product quality is stable and easy to detect

Chemical composition and stability of the product, particle size distribution are homogeneous, it is conducive to firing. The material in the vertical mill residence time of only 2 ~ 3min, but in a ball mill will have 15 ~ 20min. Therefore, the chemical composition and fineness stand mill products can be quickly measured and corrected.

6. wear small, high utilization

Since the operation of the mill stand and roller disc is no direct contact between the metal wear, metal consumption per unit of product is generally 5 ~ 10g / t.

It is because of the many advantages of vertical mill, vertical mill occupies an unshakable position in the grinding industry.