Industry Reports

The application of magnesite calcination in cement industry

Magnesite (English name for Magnesite) is a magnesium carbonate, is an almost entirely of magnesium carbonate (MgCO3) consisting of natural ore; is rhombohedral crystals, often into a compact block collection; mostly white or grey; glass lustre; lilunzu: Mg o 47.81%, apt-CO2. Density is 2.9~3.1g/cm3, the hardness 3~5. Mainly used in the manufacture of refractories and refine metal magnesium, also used in cement, rubber, paper, sugar and other chemicals, building materials and other industries.

Technical Service and Equipment Fabrication

We can provide plant design, equipment/spare parts supply, consultation and technical service for dolomite & magnesite calcination.

- More than 50 years experience in magnesium industry.

- Design capacity of single production line: 5,000-25,000 tons per year.

- Professional Process Design Engineers, Equipment Engineers, Electrical Engineers.

- Leading supplier of magnesium production line, and over 90% market share.

Process Description

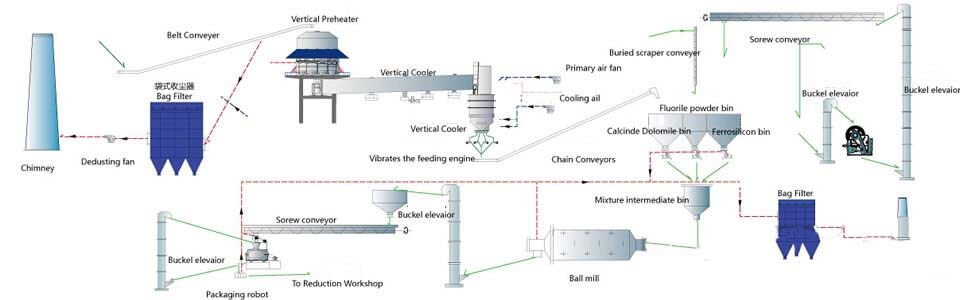

Transported by inclined Belt Conveyor, the fine crushed dolomites will be sent to the Hopper on the top of Preheater and then discharged into Preheater by feeding chute. The high temperature gas from rotary kiln can preheat the dolomites to 800℃. Some of the dolomites can dissociate after preheating. After this process, the dolomites are push out by hydraulic push-rod and get into the Rotary Kiln for calcination with 1100-1250℃ through transfer slide. After calcination, all the materials are discharged into Cooler for cooling to less than 100℃ and then discharge to next process for grinding.