Company News

Steel casting node cases

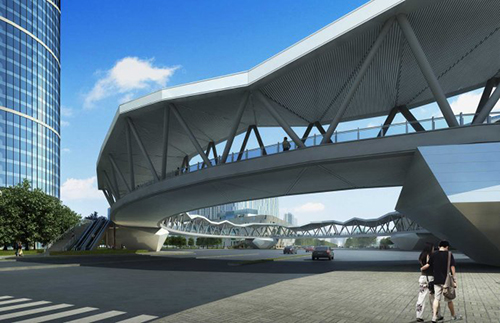

1. Project one: in 2014, the project of Shanghai Jinsha River Pedestrian Overcrossing orders 6 tons upper chord nodes with ZG20Mn5 material and intersection node with steel structure manufactured by our company is used in this project. In order to avoid the large stress of node caused by welding intersection and inconvenience of welding, cast-steel node is selected in the design, which requires material performance of cast-steel node should be equal to or better than Q420QD, wall thickness of cast-steel node should be no less than 40mm, and the minimum length of cast-steel bar should be no less than 1 meter.

However, all kinds of demanding requirements for Great Wal Machinery are the power to process high-class steel casting node. According to properties and technical requirements of Shanghai Jinsha River Pedestrian Overcrossing, Great Wal Machinery improves the casting technique of cast-steel node and finally manufactures the satisfactory cast-steel node for customers.

2. Project two: in 2013, Hangzhou Olympic Sports Center orders 55 tons steel-joining nodes from Great Wal Machinery. Design period of Hangzhou Olympic Sports Center is 100 years, belonging to the premium and large sports construction project. Awning with steel structure is lotus petal shape. There are many bars converging on the node between petals, the structure and force condition of which is complex. Single node has the features of large size, high strength of material and heavy weight. Thus, it need to find a large-scale foundry with advanced casting equipment and mature casting technology to be the supplier of node of the whole project. After careful comparison, construction party of Hangzhou Olympic Sports Center finally chooses Great Wal Machinery to manufacture all cast-steel nodes used in the project. On the one hand, Great Wal Machinery owns the domestic advanced testing equipment and inspection equipment, which can reach secondary inspection level; on the other hand, Great Wal Machinery has many successful cases in cast-steel node processing field to use for reference.

3. Project three: in 2011, Huai’an Stadium orders 4 tons arch springing steel nodes from Great Wal Machinery. Sculpt of Huai’an Stadium is novel, attractive and majestic, which is one of the few domestic large-span cable structure stadium. Because of novel structure, arch springing steel node of which adopts widely used cast-steel node at present, which has the high requirement for casting technology.

The application of cast-steel node produced by Great Wall Machinery in many buildings with steel structure also lays a foundation for this cooperation. This time, construction party of Huai’an Stadium comes to Great Wal Machinery to make an on-the-spot investigation and sign the cast-steel purchase contract with Great Wal Machinery immediately. According to the requirements of construction party of Huai’an Stadium, Great Wal Machinery makes the special treatment in the casting process of node with steel structure to ensure the quality of cast-steel node.

After the completion, with excellent design and reliable quality, Huai’an Stadium wins the 2012 annual “Jingang Award” and “2013 Gold Award of Construction Steel Structure of China (national prime-quality project)”, which proves that nodes manufactured by Great Wall Machinery meet the standards of national prime-quality project.

4. Project four: in 2011, Karamay regional digital network control center orders 5 tons nodes with steel structure from Great Wall Machinery. Because of Karamay located in Xinjiang, where is snow-prone area in China, buildings in this area must have the ability to withstand earthquake, snow and large temperature difference. As the core part in steel structure – node should have good mechanical property to ensure the stability of the whole steel structure.

At the beginning of construction of Karamay regional digital network control center, delegates of construction party comes to Great Wall Machinery to make an on-the-spot investigation, on the one hand for getting to know the strength of Great Wal Machinery, on the other hand for seeking for cooperation. Great Wal Machinery designs a set of feasible technical solution for matched cast-steel node of Karamay regional digital network control center and delegates of construction party is satisfied for that. Thus, large node product manufactured by Great Wall Machinery finally achieves the desired effect. To some extent, we can say that nodes produced by Great Wal Machinery improve the reliability and stability of the whole steel structure.