Company News

Ultrafine nickel powder grinding and processing equipment factory

First, the fine nickel powder to obtain new applications

Ultrafine nickel powder can be used to make MLCC (multi-layer ceramic capacitor) of the internal electrodes. It is reported that the company has been well-known steel production of nickel slag resources were excluded grinding processing, production of soot particles than cigarettes (about 0.5μm) less ultrafine nickel powder (0.1-0.4μm).

This electrode is used in the manufacture of ultrafine nickel powder fineness particularly good by general pulverization method is difficult to achieve the desired fineness, it is necessary to adopt a special nickel slag grinding and processing technology, the production method is the use of CVD , first nickel chloride is heated and evaporated, and then hydrogen reduction, thereby obtain fine particles. At present, this ultrafine nickel powder produced by the MLCC is widely used in the field of cars, mobile phones and so on. Life has become an indispensable material.

Second, the ultrafine nickel powder production process equipment

Ultrafine nickel powder during grinding must be carried out prior to further processing of nickel slag crushing, fine grinding process, the use of large vertical grinding mill equipment is the first step. CHAENG produced GRMS Nickel slag vertical mill become the first choice of nickel slag treatment.

CHAENG Nickel slag vertical mill equipment to satisfy customer demand for large-scale production, yield up to 180t / h, the system power consumption of less than 38kWh / t, finished product fineness can reach 480-500㎡ / kg, can meet the annual output of 200,000 to 1,500,000 tons of nickel slag production line, has been successfully applied in Indonesia 300,000 tons of nickel slag grinding production lines.

CHAENG Nickel slag vertical mill construction attaches great importance to environmental protection, the entire production line using vacuum production, with a sound of dust, noise reduction means for metering bin blanking, powder finished products and other baghouse dust points are used to govern, product delivery are used in air slides and bucket elevator, greatly reducing dust emissions and its control in 20mg / m³, far below the national 30mg / m³ standards.

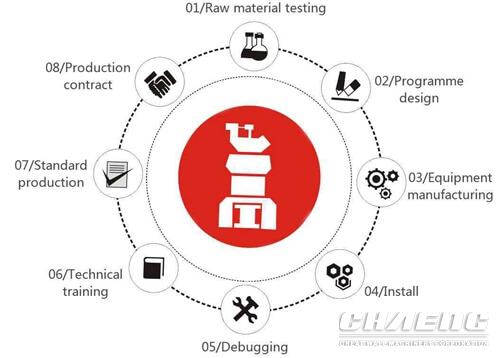

In all of the customer-centric operating principles, in order to ensure that customers throughout the nickel slag grinding project successfully conducted and completed, CHAENG launched the "One vertical mill, eight service" value-added solutions, from pre-project to the final production, CHAENG provide full guidance, praised by customers.