Company News

Pulverized coal vertical mill parameters - vertical coal mill model

All along, coal Pulverized equipment mainly wind swept coal mill,

lattice-type mill, while at the same industrial modernization, A more

energy-efficient coal vertical mill by the majority of thermal power plant

customers favorite.

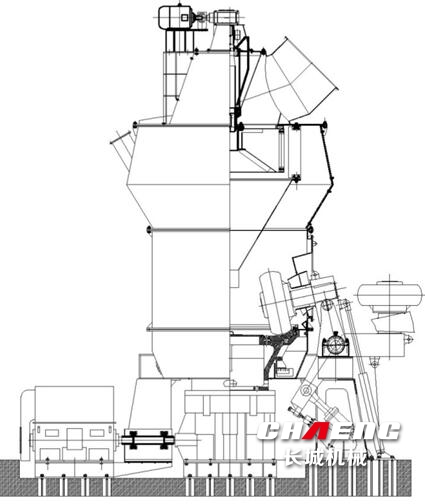

Vertical coal mill also called coal mill special for cement, power plants, steel mills and other fields of coal, bituminous materials ultrafine grinding. CHAENG production GRMC coal vertical mill with a special design and manufacturing technology, manufacturing quality to meet international advanced level, it is grinding coal, bituminous materials, efficient and clean use of coal device of choice.

First, what is coal vertical mill working principle?

Second, the technical parameters of the vertical mill

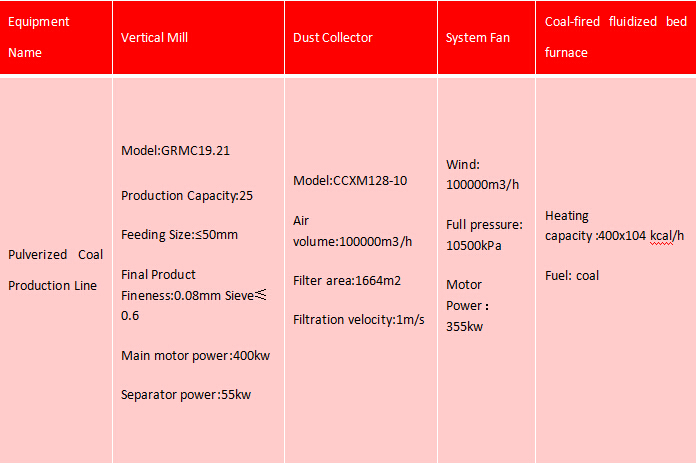

Currently CHAENG flagship 25t / h coal vertical mill, the model is GRMC19.21, which feed size of up to 50mm, coal fineness 0.08mm sieve ≤6%, the main motor power 400kw, with the separator machine motor power is 55kw.

Third, The type of GRMC 19.21 coal vertical mill advantages

1.Using the grinding material layer principle, guaranteed finish product fineness

GRMC coal mill series uses the most advanced static and dynamic modular splitter, the splitter grade high efficiency, large room for adjustment, choose powder fineness of up to 0.08 mm sieve 3%, to meet the cement production line majority of low-quality coal or anthracite grinding fineness requirements.

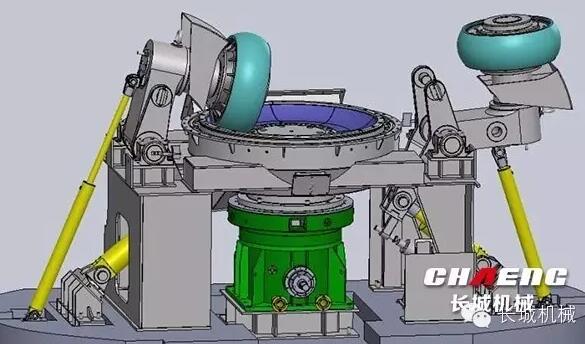

2.Optimize the roller device technology, to extend the service life

CHAENG vertical mill roller device optimization process, the roller sleeve can be used upside down. This is conducive to ensure the production, but also reduce wear and extend its life.

3.install explosion-proof devices to ensure safety in production

CHAENG coal vertical mill explosion-proof valve is provided on the housing to prevent the explosion occurred in a pulverized coal vertical mill, to ensure the safe use of equipment.

4.Green energy, clean environment

CHAENG coal vertical mill uses advanced way to grinding and energy savings compared to energy consumption by 30% to 40%; it's unique seal design, the entire system in a vacuum state, in the production process no dust spills, noise, is a green coal mill equipment.

5.The system is simple, easy to operate

The system is simple not just a simple process, more of the details of the control. CHAENG roller device using a swap-aligning roller bearings, seal chamber extends to outside the case, no contact with the dust and gas, so long as you can make a simple sealed roller bearing not into dust, no sealing fan.

6.Grinding mill transmission parts, no secondary transmission means;

Slag site simple. Coal slag vertical mill less slagging cover with no need to install slagging valve.

CHAENG constantly improve coal vertical mill technology, optimize the design, with a sophisticated heavy equipment, lean manufacturing and installation, extensive project delivery experience, and ultimately, high-quality, high environmental protection, production standards for coal vertical mill products, hundred percent to meet customer needs.