Company News

Great Wall of China in the first three mechanical slag vertical mill

The first vertical roller mill is the 1920s in Germany developed out.

It is said that vertical mill grinding principle is similar to human ancestors milled grain mill, which employs the principles of grinding material bed grinding material, ball mill grinding mechanism to overcome the many defects, high grinding efficiency, low power consumption (than the ball mill saving 20% to 30%), big drying capacity, allowing large size material into the mill, the grinding process is simple, small footprint, low construction costs, low noise, low wear, long life, easy to operate and so on.

After 90 years of development, vertical mill has been very mature, especially since the 1960s, with the large-scale warm-up pre-birth and decomposition dry process cement production lines, vertical mill in the cement industry abroad has been widely application, its technical level has been further improved and perfected.

Foreign companies have developed various types of vertical mill, were a success. Germany Loesche LM vertical mill, extraordinary company MPS vertical mill, roller mill Polysius company RM, Denmark Smith Atox vertical mill, UBE company produced UB-LM vertical mill.

Since the beginning of 2000, the Great Wall as vertical roller mill machinery industry a dark horse, quickly known and recognized by the market, slag vertical mill into the country three.

Great Wall Machinery slag vertical mill grinding energy-saving advantages:

Traditional ball mill grinding slag, system power consumption in 80kwh / t or more!

Using the Great Wall slag vertical mill grinding system power consumption in 33-40kwh / t!

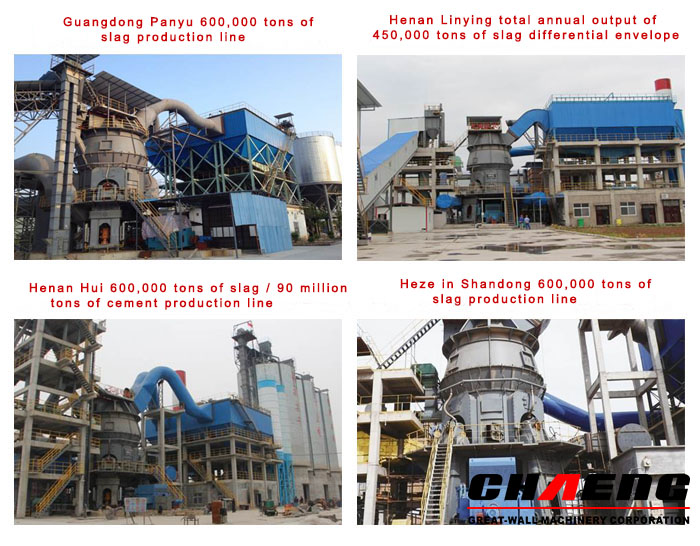

So, let us work together to enjoy the Great Wall mechanical waste production line turnkey project case: