Company News

The prices for investment slag vertical mill production line how much money

As a cement substitute an equal amount of production is important - slag powder can significantly improve the overall performance of concrete and cement products, as well as a significant reduction in cement, concrete production costs, now as a new high performance cement and concrete admixtures are Applications in cement plants, grinding plants, steel mills, has formed a "investment who should benefit whoever" situation.

Great Wall Machinery can undertake an annual output of 20-150 tons of slag / slag / nickel slag / manganese slag powder production line project EPC general contracting services, until now, the Great Wall machinery has been successfully established in more than 100 slag vertical mill production lines outside China.

In addition, the Great Wall of China machinery industry has an annual output of 600,000 tons the first demonstration training base slag powder machine and industrial waste (slag, slag, nickel slag) R & D center, extensive industry experience and strong technical capability enables mechanical energy provided from the Great Wall scientific reports, raw materials testing, engineering design, equipment manufacturing, construction, installation, commissioning, staff training, production standards, one-stop "turnkey" service.

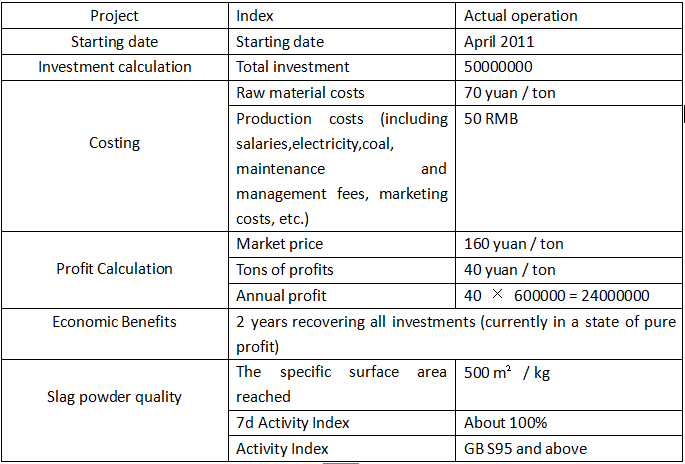

The slag line ROI display:

Xinxiang Great Wall Machinery 600,000 tons vertical roller mill production line, for example, the total investment of 50 million yuan, in April 2011 and put into production, it is already two years to recover all the investment cost of equipment, is currently in a state of pure profit. Specific costing, please refer to the following table:

Great Wall Machinery slag vertical mill resolve unique advantages:

1. The introduction of the German Loesche vertical mill technology, technology system is simple.

2. equipment operation rate, energy saving and environmental protection.

3. The system is easy to operate, save a lot of labor costs.

Picture: Great Wall Machinery slag mill stand intelligent operating system, real-time manufacturing operations risks that exist to monitor and adjust

Slag vertical mill process

Slag piled up by a forklift reclaimer, feeding, conveyed by belt conveyor. In the delivery process, the slag material has received iron and sieved through a separator and a shaker, and then weighing equipment warehouse, hoist into the vertical mill grinding. After slag grinding by means of hot air stove provided, were selected by the powder separator, at the same time get dry. In line with the required fineness slag powder it was finally delivered to the precipitator to collect, after full bloom, the air delivery chute, hoist into the finished products in storage.

To ensure that customers throughout the project successfully conducted and completed, the Great Wall machinery pioneered the industry's first "Taiwan vertical mill, eight service" value-added solutions, from pre-project to the final production, the Great Wall machinery to provide full guidance.