Industry Knowledge

700 t/d mini cement plant for export

Introduce of 700 t/d mini cement plant for sale

The design of 700 t/d mini cement plant for sale uses the most advanced five-stage suspension preheater, RSP/F decomposing furnace and cement rotary kiln. The centralized control technology will be also used in computer automation system. We are committed to offer you a perfect cement plant solution with advanced process technology and excellent facilities. All technological indexes are approvable in your local industry criteria.

The advantages of 700 t/d mini cement plant for sale

Limestone Homogenization Silo: Simple device, economically, Little Floor Space

Considering the fact that difference exists in the ingredient content of limestone, which makes the quality index difficult to control, the design uses the effective small-scale cross cut type raw material prehomogenization storage (that is, vertical prehomogenization storage) to narrow standard deviation. The homogenizing of the prehomogenization storage is 3~ 6 and discharges Ca-CO. The standard deviation being about 1.5%~2.0%. It is especially fit for small dry-process cement plant whose capacity is 700t/d.

Low Power Consumption in Raw Material Homogenizing System

Considering limited spaces in the project site, we are going to engineer a φ15 ×35m MF homogenizing silo is used to homogenize. Its effect volume is 5500t. The silo is made by the principle of gravity, so the power consumption is as low as 0. 4 - 0. 6 kWh/t.

Convenient Feeding System

There 2 sets of mechanical feed weight scales are installed at the bottom of silos. Pulverized coal is fed into the kiln head and decomposing furnace by rotary feeding device. The safe feeding system is easy to control and running perfectly.

Cyclone System

In the design, the single row layout five-stage suspension preheater is used. Except for tube C1, others are all low-pressure cyclones. Near feed points of cyclones air ducts, there are adjustable discharging boards installed to help the material scattering, preventing the material from clustering drop and causing short circuit.

The most Advanced RSP/F Decomposing Furnace

RSP/F decomposing furnace is developed on the basis of RSP technology, absorbing the advantages of MFC furnace and adding the fluidized bed. It is composed of pre-combustion chamber, calcining chamber and mixing chamber. RSP/F extends the standing time of pulverized coal and material. Due to the volume of SC and MC is enlarged properly, and fluidized bed is added, standing time of pulverized coal and material is extended to around 3.6s. The dispersiveness of material is intensified and it also enlarges the heat transfer area of whole system.

Anti-blocking Measure of Preheating System

To prevent crusting and blocking problem, poking holes as well as air cannon are engineered in the flowsheet; tricyclic compressed air purge system are installed in the C4-C5;there is bicyclic compressed air purge system in C1-C2. To know the condition of preheater timely, there is also manometer to monitor the working condition of cyclone. When the cementation blocking occurs, the monitoring device will release alarm signal such as light or sound, and the operators can deal with it directly.

Large Kiln Hood

It can increase the temperature of tertiary air effectively and makes the layout of tertiary air duct simple.

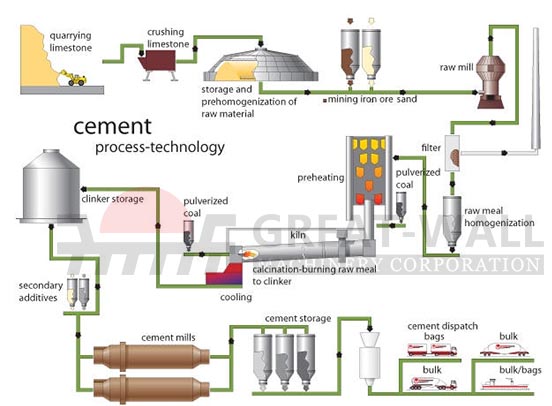

The working principle of 700 t/d mini cement plant for sale

1. Raw Mill Section :

All the raw materials should be of less than 25 mm size. If the size of the raw material is bigger than 25 mm, It has to be crushed through a crusher and Hammer Mill. All the materials are crushed stored in the storage yards through belt conveyors.

Now, the raw materials are taken as per their required percentage with the help of a weigh belts( Control by PLC ).The measured materials is went to feed belt conveyor and after that shifted to a feed hopper through elevator .The feed of material is controlled with the help if ratchet Feeder/Table feeder.

2. kiln Section :

From Surge silo the mixed raw materials are taken to Nodulizer with the help of a screw conveyor.Then water is sprayed on the mix (10%) to make nodules with the help of nodulizer. These nodules are fed into the kiln through feed chute for burning and Fusion. The temperature goes up to 1350OC in the burning zone. The material travels very slowly in the kiln. All the material get fused here. After passing through the burning zone the material starts cooling slowly. The Clinkerisation starts and the clinker finally comes out of the kiln.

3. Clinker Grinding Section :

The clinker so obtained is crushed to make its size less than 25 mm. The crushers/Roller crusher are used to crush the clinker. The Gypsum is used as an additive. Both material crushed together and went into feed hoppers through elevator. They are collected through the feeders provided below the feed hoppers. The clinker and gypsum are mixed in certain ratios (5%). So, the weigh belt is used to weigh the ingredients for mixing. A modern electronic weighing & control system may also be used to weigh and measure the ingredients The ratchet/Tables feeder is used to control the feed in the mill and control the fineness of the Cement.

700 t/d mini cement plant for sale configuration