Industry Knowledge

Great-wall rotary kiln for cement

Introduction of rotary kiln

Rotary kiln is the main equipment for dry and wet production of cement clinker and it is used to grind limestone, clay, and shale down to small bits of rock and transforms them into a usable cement mixture that is ready to be either packaged or immediately used. It allows for many similar types of solids to be broken down into more readily usable material, for example alumina, titanium dioxide, metakaolin, iron ore pellets, and many other metallic and non-metallic compositions.

Features of rotary kiln

1) Long running time before maintenance.

2) The shell of the kiln is made of mild steel plate

3) High quality supporting roller and tyre.

4) Reliable inlet and outlet seal.

5) Fixed and movable kiln head hood.

Working principle of Rotary Kiln

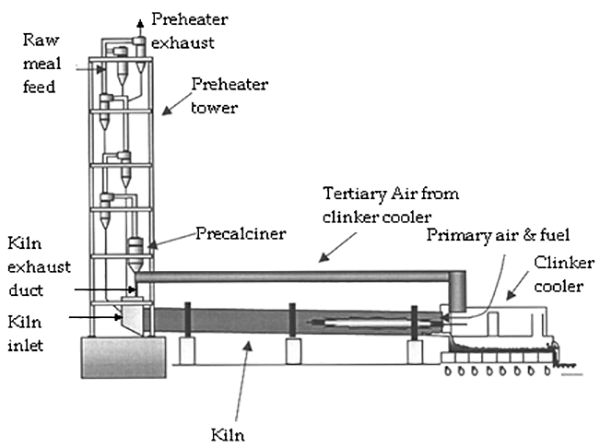

Cement raw material is fed into the upper end of the kiln. As the kiln is rotated, the material moves slowly down the kiln through a calcining zone and then a clinkering zone, and is thereafter discharged through the discharge end of the kiln into a cooler. Fuel is injected into the kiln from its lower end. As the fuel is burned in the kiln chamber, a large amount of heat is produced to sinter the limestone and clay. As hot air keeps rising along the kiln chamber, it ends up being emitted to the atmosphere via the air chimney.

Structure of rotary kiln

The rotary kiln is made of drum, support bearing, hydraulic thrust device, transmission, movable kiln head, kiln end seal, and pulverized coal injection device. The kiln body is slightly inclined to the horizontal, and is supported by hydraulic thrust roller and roller bearing.

To ensure proper functioning of the kiln even when the main power supply is cut off, we add auxiliary drive to the kiln that prevents kiln deformation. Advanced technologies ensure reliable seal at both lower and upper ends of the kiln.

Rotary kiln specifications

| Specification | Production Capacity | Main Drive | Main | Rated power | Regulating Range | Rated Voltage | Main Decelerator | Main Decelerator | Total Weight |

| (m) | (t/d) | (round/min) | Electromoter | (kw) | (round/min) | (v) | Type | Velocity Ratio | (t) |

| Type | |||||||||

| Φ2.2×50 | 96 | 0.125-1.25 | YCT280-4A | 30 | 132-1320 | 380 | ZS145-11 | 157 | 130.71 |

| Φ2.5×50 | 130 | 0.516-1.549 | YCT355-4A | 55 | 440-1320 | 380 | ZS165-7 | 99.96 | 167.5 |

| Φ3×48 | 850 | 0.3309-3.309 | ZSN4-250-21B | 90 | 100-1000 | 440 | ZS130-14 | 32.11 | 237 |

| Φ3.2×48 | 1000 | 0.375-3.75 | ZSN4-280-21B | 160 | 100-1000 | 440 | NZS1240-28 | 27.469 | 252 |

| Φ3.2×50 | 1200 | 0.398-3.975 | ZSN4-280-11B | 190 | 150-1500 | 440 | ZL130-16 | 40.85 | 263 |

| Φ3.3×52 | 1200 | 0.391-3.91 | ZSN4-355-082 | 190 | 100-1000 | 440 | ZSY500-28 | 27.707 | 280.8 |

| Φ4×60 | 2500 | 0.396-3.96 | ZSN4-355-092 | 315 | 100-1000 | 440 | ZSY630-35.5 | 34.601 | 487.5 |

| Φ4.2×60 | 2800 | 0.4165-4.165 | ZSN4-355-12 | 420 | 100-1000 | 440 | ZSY710-35.5 | 35.526 | 576.1 |

| Φ4.3×62 | 3000 | 0.398-3.98 | ZSN4-355-12 | 420 | 100-1000 | 440 | ZSY710-35.5 | 35.714 | 598.5 |

| Φ4.3×64 | 3200 | 0.449~4.49 | ZSN4-355-12 | 450 | 100~1000 | 440 | JH630C-SW305-25 | 24.365 | 585 |

| Φ4.5×66 | 4000 | 0.41~4.1 | ZSN4-400-22 | 630 | 100~1000 | 660 | JH800C-SW306-35.5 | 34.069 | 710.4 |

| Φ4.8×70 | 5000~5500 | 0.4~4.0 | ZSN4-400-22 | 630 | 100-1000 | 660 | JH800C-SW306-31.5 | 30.876 | 845.3 |

| Φ4.8×72 | 5000 | 0.403~4.03 | ZSN4-400-22 | 560 | 100~1000 | 660 | YNS1760-31.5VDR | 30.365 | 847 |

| Φ4.8×74 | 5000 | 0.35~4 | ZSN4-400-092 | 630 | 130~1500 | 660 | JH710C-SW305-40 | 42.226 | 841 |

Brief Introduction of Xinxiang Great Wall Machinery

Xinxiang Great Wall Machinery Co., Ltd was built in 1958. Covering an area of 330,000 square meter and having more than 1,100 employees, the company has a total asset of RMB 450 million and has passed through ISO9001:2008 quality management system certification, possessing the experience of equipment manufacturing for more than half a century, has formed the perfect operation and management system in design and development, product manufacturing, market promotion, equipment installation and after sales service.